A Laboratory Raising Hearth Furnace is a specialized piece of equipment used primarily in laboratories for heating and heating-related applications, offering precise control over temperature, environment, and the heating process itself. Whether you’re conducting experiments, performing tests, or processing materials, this furnace is invaluable for a range of scientific and industrial purposes. In this blog post, we'll dive deep into what a laboratory raising hearth furnace is, its components, working principles, applications, and benefits.

Introduction to the Laboratory Raising Hearth Furnace

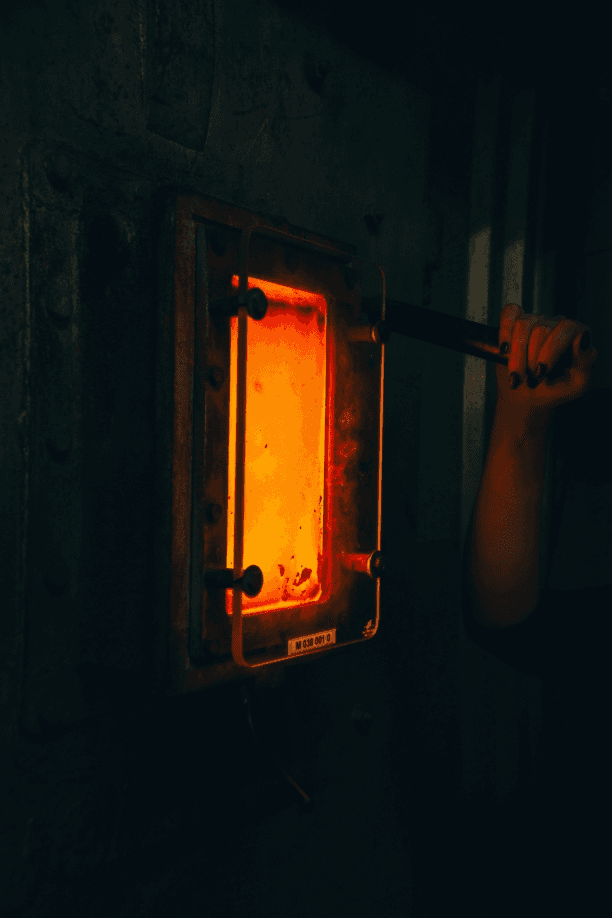

A raising hearth furnace is a specialized laboratory furnace designed for accurate heating and material processing. It operates with a unique mechanism that allows the height of the heating chamber to be adjusted, giving it the flexibility to handle various materials more effectively. The furnace's hearth, where the materials are placed, can be raised or lowered, allowing for precise control over the heat exposure. This adjustability ensures better temperature regulation, making it an ideal choice for laboratory applications that demand high levels of precision, versatility, and consistency.

How Does a Laboratory Raising Hearth Furnace Work?

The operation of a laboratory raising hearth furnace centres around its hearth (also called the furnace floor). Unlike traditional furnaces where the material remains stationary during heating, a raising hearth furnace allows the hearth to be raised or lowered depending on the heating requirement. This ability to control the height of the material relative to the heat source can result in:

- Uniform heating: Raising or lowering the material ensures an even distribution of heat.

- Adjustable exposure time: The speed at which the material is heated or cooled can be controlled by the position of the hearth.

- Precise temperature control: Operators can ensure that the material is exposed to a consistent temperature, crucial for specific laboratory experiments.

A heating element (electric or gas-powered) is placed beneath or around the hearth. Temperature sensors ensure that the heat remains within a pre-defined range. The operator can also adjust the airflow and atmosphere to further control the material's heating conditions.

Key Components of a Laboratory Raising Hearth Furnace

A laboratory raising hearth furnace consists of several important components that ensure its smooth operation:

- Hearth Platform: The primary area where materials are placed for heating. This platform can be raised or lowered for precise temperature control.

- Heating Element: The furnace is usually powered by either electric or gas heating elements, which provide the heat required for the process.

- Temperature Controls and Sensors: Integrated into the furnace, these components monitor and adjust the temperature inside the furnace to ensure uniform heating.

- Insulation: A high-quality insulating layer ensures minimal heat loss, helping the furnace maintain temperature stability.

- Gas Supply and Ventilation: Some raising hearth furnaces are equipped with a gas supply for creating an atmosphere inside the furnace, which can be important for some types of material processing.

- Control Panel: The operator uses this interface to adjust temperature, heating time, and other parameters.

Applications of a Raising Hearth Furnace

Laboratory raising hearth furnaces are used in a variety of fields, including:

- Material Science: Used for heating samples to study the effects of temperature on materials, such as in metallurgical tests, ceramic production, and alloy processing.

- Heat Treatment: Used to apply controlled heat to materials in order to modify their physical properties, such as hardening or tempering metals.

- Testing of Industrial Components: Raising hearth furnaces are ideal for testing the heat resistance and other properties of materials used in high-performance applications.

- Chemical Analysis: Certain chemicals require precise and controlled heating for analysis, such as in the production of fine chemicals or pharmaceutical compounds.

- Forensic and Archaeological Analysis: Researchers can use these furnaces to heat specimens for detailed forensic or archaeological testing.

Benefits of Using a Laboratory Raising Hearth Furnace

A laboratory raising hearth furnace provides numerous advantages in a lab setting, including:

- Precise Control: The ability to adjust the heating process to exact specifications, ensuring consistent results.

- Flexibility: Different materials can be processed by adjusting the temperature, atmosphere, and exposure time.

- Efficiency: The design minimizes heat loss, reducing energy consumption and increasing overall efficiency.

- Safety: The controlled environment reduces the risk of overheating or other dangerous scenarios. Many models come with automatic shut-off features in case of malfunction.

- Versatility: It can be used in a variety of applications across different industries, from metals processing to chemical production.

Choosing the Right Laboratory Raising Hearth Furnace

When choosing the appropriate raising hearth furnace for your laboratory requirements, consider the following considerations:

- Temperature Range: Ensure the furnace can reach the temperatures necessary for your specific applications.

- Size and Capacity: Depending on the scale of your operations, you might need a furnace with a larger or smaller hearth.

- Control System: Advanced control systems allow for better automation, data logging, and remote monitoring. This is especially useful for complex experiments.

- Energy Source: Decide whether you need an electric furnace or a gas-powered one, based on your specific needs and available resources.

- Material Compatibility: Ensure the furnace materials are compatible with the type of material you plan to heat, especially if you’re dealing with corrosive or reactive substances.

A laboratory raising hearth furnace is a critical tool for many scientific and industrial applications, offering precise control over temperature and heating conditions. Whether you’re working with metals, ceramics, or chemicals, this furnace type provides versatility, efficiency, and accuracy. By understanding how these furnaces work and their benefits, you can make an informed decision about incorporating one into your lab operations.

If you’re in the process of choosing a furnace for your laboratory, take the time to assess your specific needs, and invest in a high-quality unit that will ensure safe and efficient material processing. The raising hearth furnace is an invaluable asset to any lab looking for consistent, precise, and high-quality results.