In the world of thermal processing, the microwave furnace is revolutionizing how materials are heated, sintered, and refined. Tasks that once required hours of intense energy and high temperatures can now often be completed faster, cleaner, and more efficiently—thanks to the unique capabilities of microwave energy and electromagnetic radiation.

In this blog, we’ll explore the fundamentals of how a microwave furnace works, examine the science behind microwave heating, and consider the benefits and challenges across both industrial and research applications.

What Is a Microwave Furnace?

A microwave furnace is a thermal processing system that uses microwave energy—typically at 2.45 GHz, the same frequency used in household microwave ovens—to heat materials. Unlike conventional furnaces, which rely on external heating elements, a microwave furnace heats material from Microwave Energy the inside out by exciting molecules within the material using electromagnetic radiation.

The Core Principle: Dielectric Heating

At the heart of microwave furnace technology lies a phenomenon known as dielectric heating. When a dielectric (non-conductive) material is exposed to microwave radiation:

- Polar molecules (such as water or certain ceramics) attempt to align with the rapidly alternating electric field.

- This continuous molecular reorientation causes internal friction.

- That friction generates heat directly within the material.

Dielectric heating produces internal heat, allowing microwaves to heat materials quickly and evenly, which provides clear benefits compared to conventional surface-heating techniques.

Key Components of a Microwave Furnace

A typical microwave furnace includes the following components:

1. Magnetron or Microwave Generator

- Produces microwave energy at 2.45 GHz

- Converts electrical energy into electromagnetic radiation

2. Waveguide

- A waveguide directs microwaves from the magnetron to the processing chamber

- Ensures efficient delivery of microwave energy

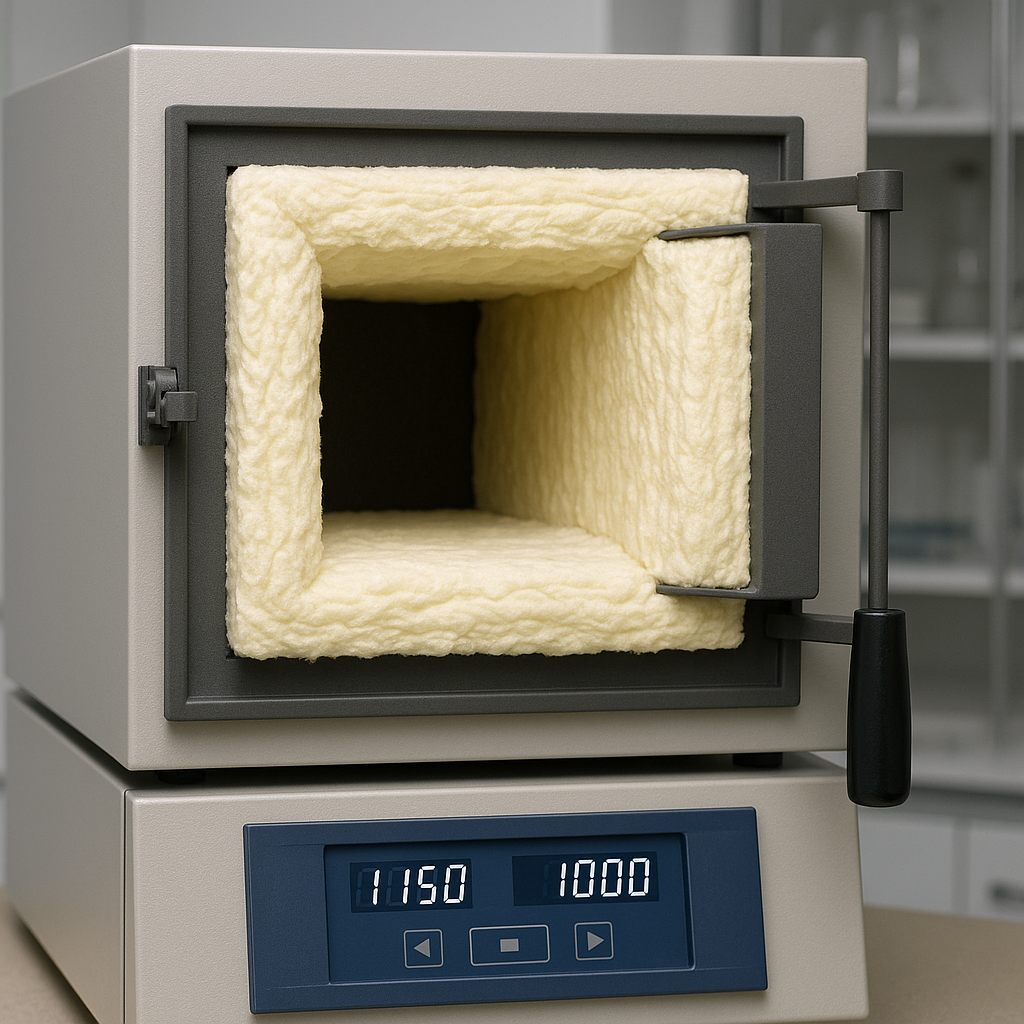

3. Cavity (Processing Chamber)

- The main chamber where materials are placed

- Usually constructed with materials that allow microwaves to pass through and are insulated to retain heat

4. Susceptor (Optional)

- A material such as silicon carbide (SiC) or graphite that absorbs microwave energy

- Aids in initiating microwave heating in non-absorbing materials

5. Thermal Insulation and Control System

- Maintains desired temperatures and protects external components

- Uses thermocouples, infrared sensors, or fibre optics for real-time temperature monitoring and control

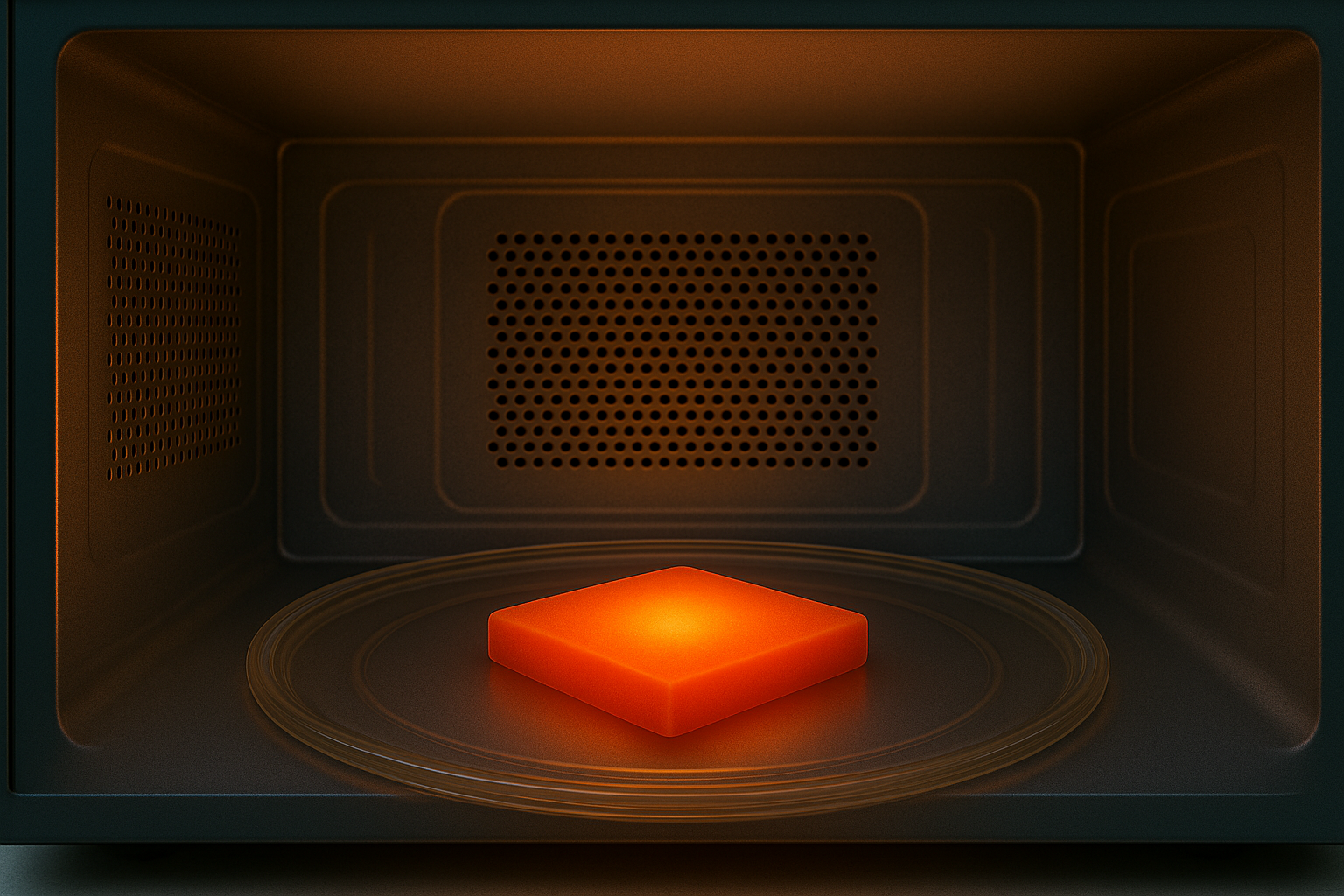

How Heating Happens in a Microwave Furnace

Here’s a simplified overview of how microwave heating works in a microwave furnace:

- The magnetron emits electromagnetic radiation into the chamber.

- A waveguide channels the microwave energy to the material.

- The molecules inside the material become energized, producing heat as a result of dielectric heating.

- Temperature rises rapidly and uniformly.

- A control system monitors and adjusts power output to maintain optimal conditions.

Materials That Can Be Processed

Microwave furnaces offer great flexibility and can handle the processing of various types of materials:

- Ceramics and Glass – Benefit from fast, uniform sintering via microwave heating

- Metals and Alloys – Often require susceptors or hybrid systems for effective heating

- Polymers and Composites – Used in joining, bonding, and curing applications

- Nanomaterials – Ideal for fine-particle synthesis with precise thermal control

- E-waste – Enables efficient metal recovery and recycling

Benefits of Microwave Furnace Technology

Faster Heating Rates

A microwave furnace allows for significantly quicker heating compared to traditional methods:

- Volumetric microwave heating heats materials from the inside out

- Typical heating rates can exceed 100°C per minute

- Instant response—electromagnetic radiation acts immediately

- Well-suited for quick sintering processes and improved manufacturing efficiency

Improved Energy Efficiency

Microwave heating is highly targeted and energy-efficient:

- Minimal energy loss since heat is generated within the material

- Only the material is heated—not the entire chamber

- Energy usage can be 20–50% lower than traditional systems

- Contributes to reduced expenses and promotes environmentally sustainable practices

Enhanced Temperature Control

Microwave furnaces offer superior control and consistency:

- Uniform microwave heating reduces thermal gradients

- Advanced sensors ensure accurate temperature regulation

- Lower risk of cracks and internal stress in delicate materials like ceramics

Long-Term Cost Savings

Though the initial investment may be higher, a microwave furnace pays off in the long run:

- Reduced energy bills from efficient microwave heating

- Shorter processing times increase throughput

- Lower maintenance costs—no conventional heating elements

- Longer lifespan for components due to less thermal fatigue

Environmentally Friendly

Microwave furnace technology aligns with green manufacturing practices:

- Lower carbon footprint due to reduced energy use

- Minimal emissions—especially compared to combustion-based systems

- Cleaner processes suitable for recycling and sustainable sintering

- Supports circular economy models (e.g., metal reclamation from e-waste)

Safer, Cleaner Operations

Microwave furnaces offer safer operating environments:

- No open flames or combustion

- Cooler outer surfaces reduce risk of burns

- Minimal toxic by-products—ideal for labs and cleanrooms

- Integrated safety systems prevent accidental exposure to microwaves

Enabling Innovation and Advanced Materials

The microwave furnace is at the forefront of next-generation materials research:

- Precise microwave heating enables nanomaterial synthesis

- Supports production of smart and functionally graded materials

- Expands compatibility through hybrid heating (microwave + induction)

- Key technology for advanced ceramics, composites, and alloy development

Challenges and Limitations

Despite its advantages, microwave furnace technology has a few limitations:

- Risk of non-uniform heating in materials that absorb microwaves unevenly

- Not all materials respond well to microwave energy

- Scaling up for industrial use can be complex and costly

- Involves higher initial costs compared to traditional systems

Future Outlook

As industries prioritize sustainability, innovation, and efficiency, microwave furnace technology is becoming increasingly relevant in areas such as:

- Green metallurgy

- Advanced ceramics

- Electronic and battery materials

- Additive manufacturing (3D printing)

Ongoing advancements in microwave heating, automation, and hybrid systems are expected to expand adoption and reduce barriers to entry.

The microwave furnace marks a significant advancement in thermal processing. Leveraging microwave energy, dielectric heating, and targeted microwave heating, it provides faster, cleaner, and more controlled processing than traditional methods. From laboratory-scale research to full-scale industrial production, this technology is reshaping how materials are treated. Whether you're in metallurgy, nanotechnology, ceramics, or sustainable manufacturing, the microwave furnace is a powerful solution worth serious consideration.