How Furnaces Power Modern Industry: From Metals to Medicine

Furnaces are essential equipment that generate heat in a regulated manner, often by combusting a fuel source. These specialized machines can reach temperatures of up to 1,800 °C, making them indispensable across various industries and laboratories. From large-scale industrial processes to precise laboratory applications, furnaces are critical tools for heating, melting, and processing materials.

In this blog, we will explore some of the most commonly used furnaces across different industries and their specific applications.

Blast Furnace in the Metallurgical Industry

The blast furnace is a cornerstone of the metallurgical industry, primarily used for the extraction of iron from its ore, such as iron ore. This process, known as smelting, involves reducing raw iron ore to iron through a chemical reaction with coke (a carbon-rich material) and limestone (calcium carbonate). Blast furnaces are crucial for large-scale iron production, which supports industries such as construction, automotive, and machinery manufacturing.

Rotary Tube Furnace in the Ceramic Industry

Rotary tube furnaces are widely used in industries requiring high-temperature processing of materials under controlled conditions. The rotating action of the furnace ensures uniform heating and efficient processing of powders, granules, or other bulk materials. In the ceramic industry, these furnaces are utilized for

- Sintering: Ensuring ceramic particles fuse together without melting

- Calcination: Processing raw materials like clays and minerals to produce ceramic or refractory products

Regenerative Furnace in the Glass Industry

Regenerative furnaces are essential for large-scale, continuous glass production, efficiently melting materials like silica sand, soda ash, and limestone. These furnaces utilize regenerative chambers filled with refractory material to alternate the flow of hot exhaust gases and incoming combustion air, preheating the air to enhance thermal efficiency. Widely used in the production of flat glass, container glass, and float glass, they offer significant advantages, including high energy efficiency through heat recovery, reduced fuel consumption, large production capacity, and consistent melt quality. Their ability to maintain stable temperatures and minimize energy costs makes them the preferred choice for high-volume glass manufacturing.

Muffle Furnace in the Food Industry

To ensure food quality, various tests are conducted, one of which is ash testing. Ash testing determines the amount of minerals and micronutrients present in food products.

For this purpose, muffle furnaces are widely used to combust food samples, turning them into ash without external interference. The ash is the inorganic residue remaining after removing water and organic matter by heating in the presence of oxidizing agents. This process ensures accurate testing of mineral content in food products.

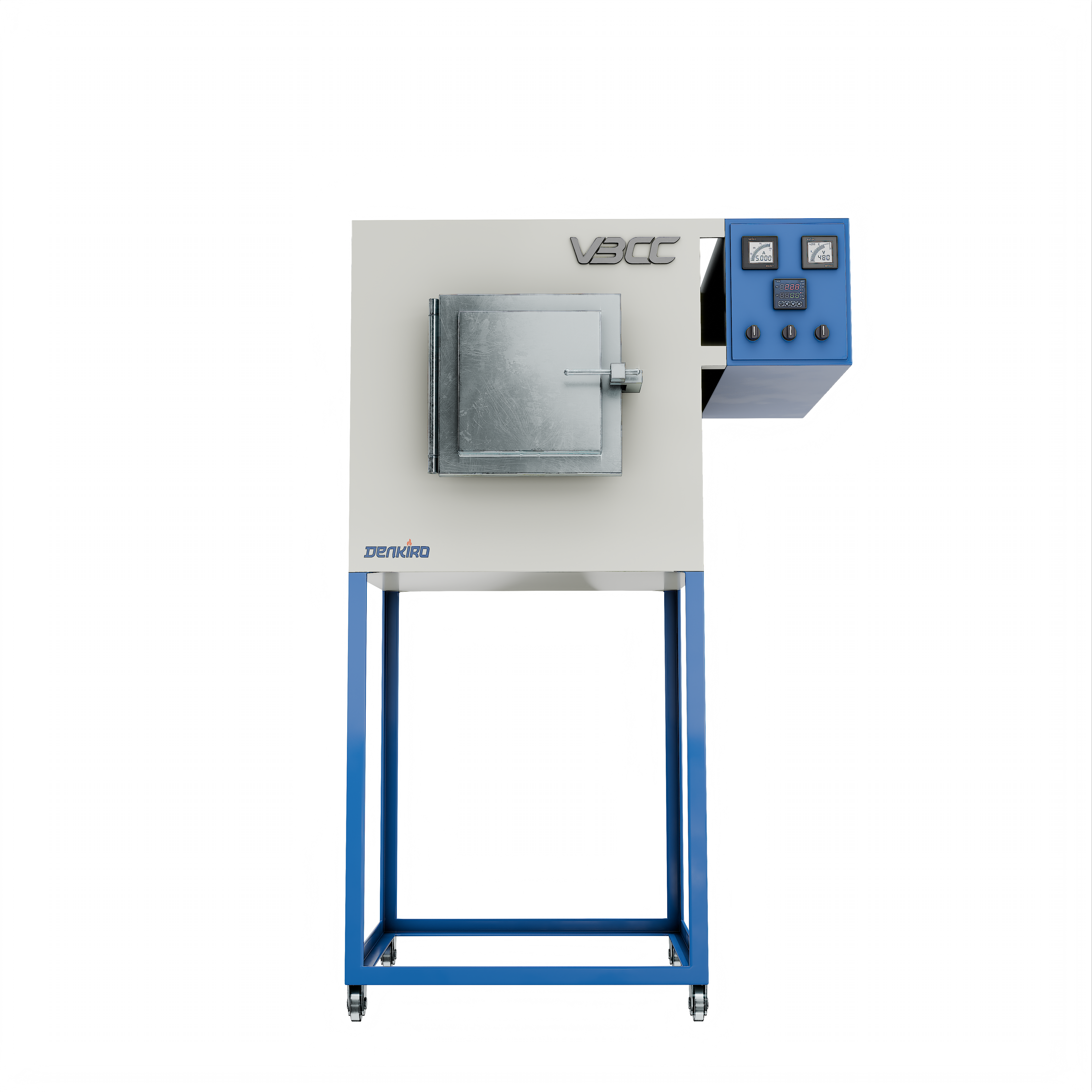

Vacuum Furnace in the Pharmaceutical Industry

Vacuum furnaces play a critical role in the pharmaceutical and medical sectors, enabling processes that require precise temperature control and contamination-free environments. These furnaces are utilized for

- Sintering: Manufacturing medical implants and components

- Heat Treatment: Treating metals for medical devices

- Sterilization: Ensuring the safety of medical equipment

- Drying: Processing pharmaceutical powders and active ingredients

- Desolvation and Dehydration: Removing solvents and water from pharmaceutical formulations

- Composite Material Processing: Producing high-precision medical equipment and devices

Vacuum furnaces ensure the quality, safety, and effectiveness of medical devices, implants, and pharmaceutical products through their controlled environments and precise high-temperature processing.

Furnaces are vital for powering modern industries, supporting processes from smelting metals to producing high-quality medical devices. Whether it’s the blast furnace in the metallurgical industry, the regenerative furnace in glass manufacturing, or the vacuum furnace in the pharmaceutical sector, these technologies enable innovation and efficiency across diverse applications. By understanding their roles, we can appreciate how these machines contribute to industrial progress and quality assurance.