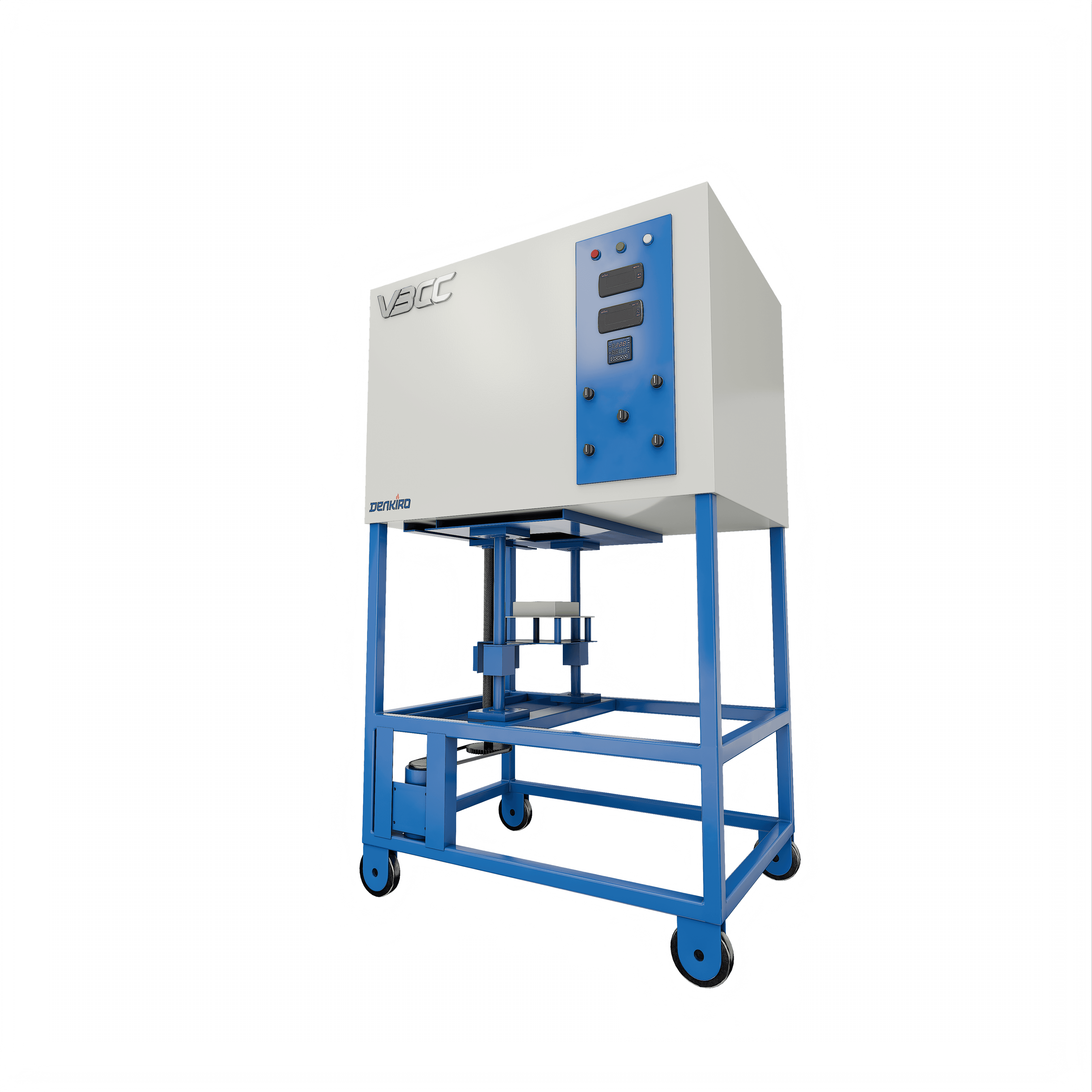

Box or Muffle Furnace

VBCC’s meticulously designed box furnace, or muffle furnace, delivers a great compact solution for labs with limited space. The microprocessor temperature control provides excellent stability and uniformity, while the thermal mass assures fast heating times with low power consumption.

- Compact Design :Space-saving dimensions ranging from 150 x 150 x 150 mm to 300 x 300 x 300 mm, offering versatility to accommodate various sample sizes and quantities.

- High-Quality Construction :Double-wall construction with MS body and angle structure ensures durability and stability, while the powder coat painting enhances aesthetics and corrosion resistance.

- Efficient Heat Retention :Stainless steel door with sophisticated insulation system minimizes heat loss, equipped with a chain mechanism for smooth and reliable operation.

- Front-Loading Convenience :Horizontal front-loading design facilitates easy loading and unloading of samples, optimizing workflow efficiency.

- High-Performance Heating Elements :Employs APM Kanthal heating elements, providing reliable heating performance up to 1200°C for continuous operation. Designed to accommodate different heating element materials such as silicon carbide for 1400°C and Super Kanthal from 1600°C.

- Precise Temperature Control :TAIE microprocessor-based PID- 18*8=144 Segments offers precise temperature regulation with an accuracy of ±1°C, ensuring optimal process control.

- Rapid Heating/Cooling :Capable of achieving heating/cooling rates from 1 to 10°C per minute, enabling quick ramp-up and cooldown times for efficient processing.

- User-Friendly Interface :Intuitive control switches for mains and output, along with digital temperature display and ammeters, provide easy operation and monitoring.

- Reliable Temperature Sensing :'K' type thermocouples (Chromel/Alumel) ensure accurate temperature measurement, essential for consistent results.

- Safe Operation :Equipped with input and output fuses for added safety, ensuring protection against electrical faults.

- Adaptable Power Requirements :Single-phase operation at 230V AC with a maximum power requirement of 4 kW, offering flexibility in power supply arrangements.

- Customizable Heating :Allows for precise control of the heating process through phase angle-controlled thyristors imported from SEMIKRON, Italy, ensuring stable and efficient power management.

- Wide Temperature Range :Capable of operating at a maximum temperature of 1800°C, ideal for a variety of heat treatment and material testing applications.

- Versatile Applications :Suitable for a range of industrial and laboratory applications, including annealing, sintering, and material research, offering reliable performance and consistent results.

More laboratory Furnaces

Box Type Vacuum Furnace