In a world where material performance is everything—from aerospace to everyday electronics—thermal conductivity plays a vital role. Whether you're engineering a heat sink for a processor or insulating a building, understanding how heat travels through materials is essential. A highly reliable method for analysing this property involves using a thermal conductivity apparatus.

So, what exactly is thermal conductivity? And how does the apparatus help us measure it? Let’s dive into the science that makes this phenomenon so important.

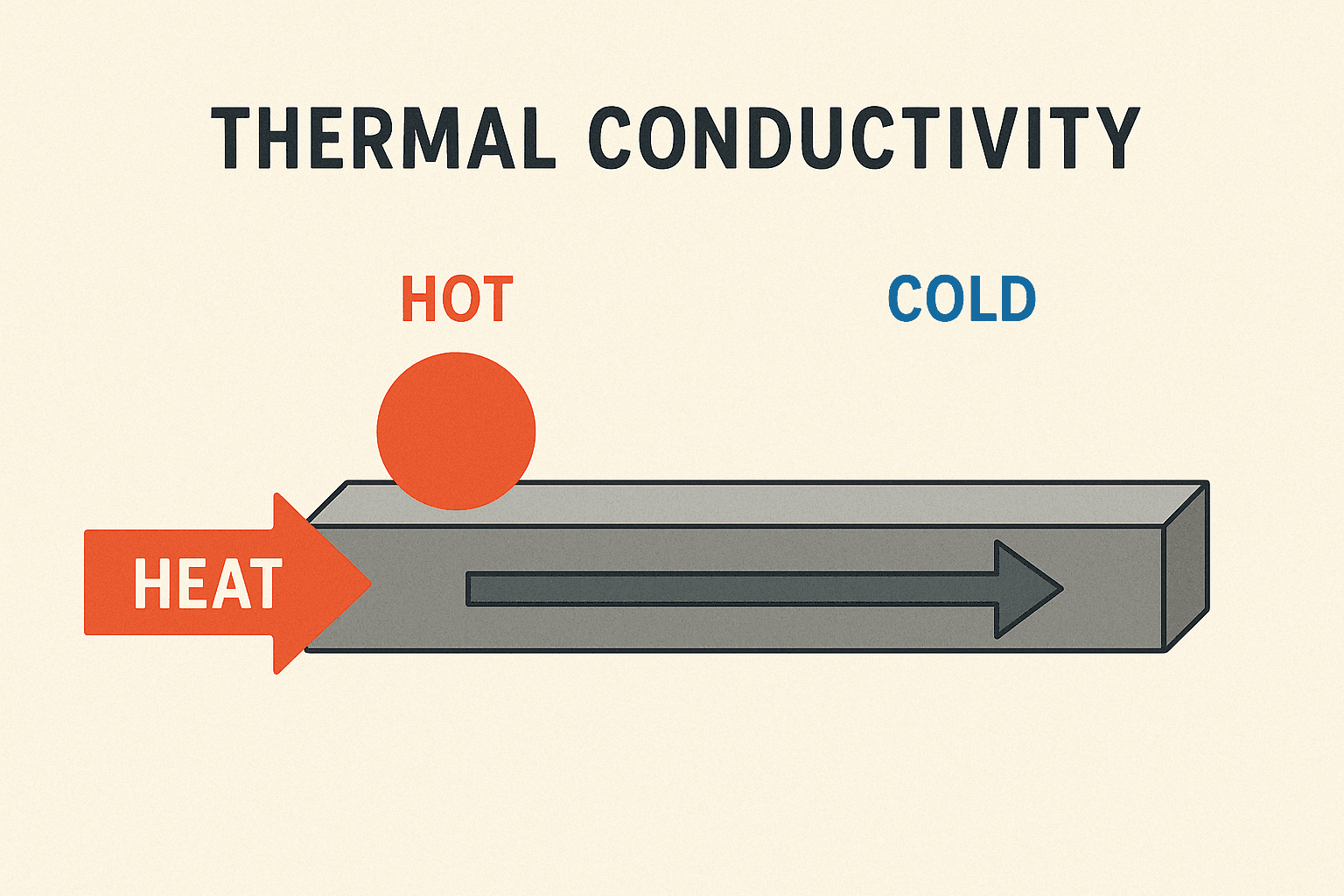

What is Thermal Conductivity?

This property measures a material's capacity to transmit thermal energy. In simple terms, it tells us how quickly heat passes through a substance. Mathematically, it's defined as:

k = Q. L /A. ΔT

Where:

- k: Represents the thermal conductivity of a material—how effectively it transfers heat. Its unit is watts per meter per kelvin (W/m·K).

- Q: Denotes the rate of heat transfer, measured in watts (W), indicating the amount of heat energy transferred per second.

- L: Refers to the distance or thickness the heat must travel through the material, given in meters (m).

- A: Stands for the cross-sectional area perpendicular to the direction of heat flow, measured in square meters (m²).

- ΔT: Indicates the temperature gradient between two points in the material, expressed in kelvins (K).

High thermal conductivity materials (like copper or aluminium) transfer heat quickly, while low thermal conductivity materials (like wood or polystyrene) act as insulators.

Why is Measuring Thermal Conductivity Important?

Understanding thermal conductivity helps in:

- Material selection for insulation, electronics, or engines

- Safety design in systems exposed to extreme temperatures

- Enhancing energy performance in homes and devices

- Optimizing energy use in construction and electronics

- Quality control in manufacturing processes

The Thermal Conductivity Apparatus: Core Function

A thermal conductivity apparatus is an instrument commonly used in labs to determine how well a material transfers heat. While the design may vary, the principle remains the same: apply heat to one end of a specimen and measure the temperature difference across it.

How Does It Work?

Most standard thermal conductivity apparatuses follow one of the following methods:

1. Guarded Hot Plate Method

- A flat specimen is placed between two plates—one heated, the other cooled.

- The steady-state temperature gradient is measured.

- It's widely used for insulating materials.

2. Searle’s Bar Method

- Common in academic labs.

- Heat is applied to one side of the metal rod, and temperatures are measured at predetermined points.

- A steady-state condition is achieved before measurements are taken.

3. Heat Flow Meter Method

- Uses thermopiles to detect and quantify heat passing through a material sample.

- Well-suited for rapid assessments and quality assurance in industrial settings.

Key Components of the Apparatus

A thermal conductivity apparatus is a carefully engineered setup designed to deliver accurate and repeatable measurements. While designs can vary depending on the testing method and material type, most setups share several core components, each serving a specific function in the heat transfer process:

1. Heat Source

The heat source provides a controlled and steady supply of thermal energy to one side of the test specimen. Common types include:

- Electric Heaters: Often embedded in a metal block or plate, they ensure even heat distribution.

- Hot Plates: Used in simpler configurations like the Searle’s Bar method.

- Guarded Heaters: Found in high-precision devices to minimize lateral heat losses.

A steady supply of heat is essential to maintain a consistent temperature difference across the sample.

2. Sample Holder or Test Chamber

This is where the material specimen is placed. Its role is to:

- Keep the sample securely in place.

- Ensure uniform thermal contact.

- Prevent heat leakage from undesired pathways.

Some advanced holders are designed with spring-loaded clamps or vacuum chambers to improve thermal contact and reduce convective losses.

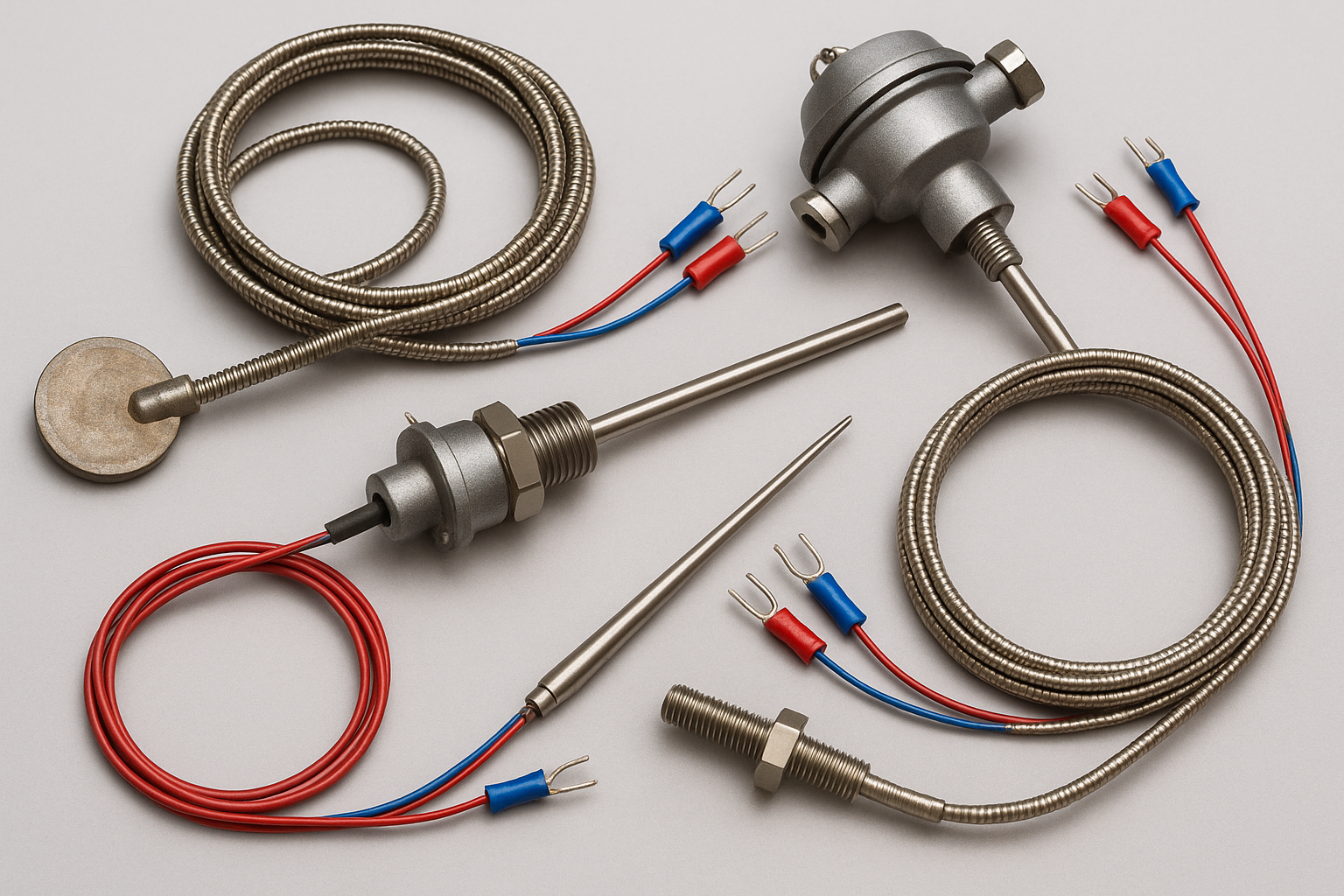

3. Temperature Sensors (Thermocouples or RTDs)

Temperature measurements are crucial for calculating thermal conductivity. These sensors:

- Detect temperature differences across the specimen.

- Are placed at precise intervals along the heat flow path.

- Include thermocouples (Type K or T) for fast response or RTDs (Resistance Temperature Detectors) for high accuracy.

Multiple sensors ensure temperature uniformity checks and error minimization in calculations.

4. Cooling or Heat Sink Mechanism

To create a measurable temperature gradient, the opposite end of the specimen needs to be kept cool. This may involve:

- Water-cooled plates

- Finned heat sinks

- Passive radiative cooling surfaces

Efficient cooling helps reach steady-state conditions faster and keeps the system thermally stable.

5. Insulation Enclosure

Surrounding the experimental setup with insulation helps:

- Minimize heat losses to the environment.

- Direct heat flow mainly along a single axis.

- Improve result reliability and measurement accuracy.

Common insulating materials include foam boards, fiberglass, or ceramic fibre blankets.

6. Data Acquisition System (DAQ)

Modern apparatuses include a digital system to:

- Log temperature readings in real-time.

- Control heating power automatically.

- Display calculated thermal conductivity values.

Some systems come with PC interfaces or software for advanced data visualization, plotting temperature profiles, or performing automated error analysis.

7. Calibration Standards (Optional but Important)

For accurate results, the setup must be regularly calibrated using materials with known thermal conductivity values. This step ensures:

- Instrument reliability

- Error tracking over time

- Ensuring standards in both educational and industrial experiments

Common Materials Tested

- Metals (copper, aluminium, brass)

- Ceramics

- Polymers and plastics

- Building insulation materials (fiberglass, foam, etc.)

Challenges in Measurement

Measuring thermal conductivity isn’t always straightforward:

- Achieving steady-state conditions can take time.

- Heat escaping to the environment can affect the accuracy of the results.

- The accuracy of measurements can be influenced by the thermal resistance at the interface between the sample and the equipment.

Well-designed apparatuses mitigate these through careful insulation, calibration, and control systems.

The thermal conductivity apparatus may seem like just another piece of lab equipment, but the science it reveals is fundamental to modern technology and engineering. Understanding how heat moves through materials allows for the development of systems that are safer, more efficient, and better optimized for energy use.

Whether you're a student learning about thermodynamics or a researcher pushing the limits of material science, grasping the principles of thermal conductivity—and how we measure it—is a crucial step forward.