High-temperature processing demands a delicate balance of precision, efficiency, and safety—requirements that tiltable tubular furnaces are uniquely equipped to meet. With their combination of uniform heating and controlled tilting for safe material handling, these furnaces go far beyond basic lab applications. They serve as essential tools across a wide range of industries, each leveraging their capabilities to drive innovation and advance material technologies. Let’s explore how various sectors are putting this specialized equipment to work.

1. Metallurgy & Materials Science

Metallurgical research and alloy development demand controlled environments that can simulate real-world conditions while ensuring safety. Tiltable tubular furnaces provide uniform heating across a tubular chamber, enabling research teams to melt metals and analyse thermal behaviours with precision.

Key applications include:

- Alloy Formulation: With the ability to control the pouring process, researchers can safely melt and mix metals in small batches. This proves critical when developing new alloys or optimizing existing metal compositions.

- Phase Change Studies: The precise temperature control in these furnaces helps study the phase transitions of metals. This insight assists in tailoring properties like hardness, ductility, and corrosion resistance.

- Thermal Stress Analysis: Uniform heating minimizes thermal gradients, allowing scientists to study stress and strain during rapid heating and cooling cycles without compromising the integrity of the sample.

Impact on Research:

By reducing manual handling and limiting contamination risks, tiltable tubular furnaces directly contribute to producing higher-quality experimental data and enhancing research reproducibility.

2. Advanced Ceramics & Glass Processing

The production and experimentation with high-performance ceramics and glass materials require environments with exact thermal regulation and safe material handling. Tiltable tubular furnaces bridge these requirements by ensuring even heat distribution and enabling safe pouring procedures.

Why they’re indispensable:

- Sintering of Ceramics: By providing controlled atmospheres—often inert or reducing gas environments—these furnaces promote even sintering of ceramic powders. This process leads to ceramics with enhanced mechanical strength and improved thermal performance.

- Glass Melting & Casting: The tilting mechanism is integral when casting glass into molds. It allows for gentle, controlled pouring, preventing the formation of bubbles or defects in the final product.

- Optical Material Synthesis: For researchers developing specialized glass for lenses or fibre optics, the furnace offers a reliable means to achieve the consistency and purity required for high optical clarity.

Impact on Industry:

These capabilities facilitate innovation in fields such as electronics, medical devices, and telecommunications, where advanced ceramics and glass play a pivotal role in performance and durability.

3. Aerospace & Defence R&D

The aerospace and defense sectors frequently require materials capable of withstanding extreme environments and intense operational stresses. In these high-stakes fields, new alloys and composites must undergo rapid prototyping and thorough testing under demanding conditions. Tiltable tubular furnaces meet these needs by providing controlled melting environments that accurately simulate rigorous operating scenarios.

Common applications:

- Heat-Resistant Alloy Development: Experiments with materials like titanium and Inconel benefit from the precise temperature control of these furnaces, which is critical when designing alloys that must withstand extreme heat and stress.

- Prototype Testing: Small-batch melting and casting enable rapid iteration during the prototyping phase, accelerating the development cycle of aerospace components.

- Simulation of Re-entry Conditions: The uniform heating properties of tiltable furnaces allow for controlled experiments that mimic the extreme thermal conditions encountered during atmospheric re-entry.

Impact on Innovation:

By enabling safer handling and more refined processing of high-performance materials, these furnaces contribute significantly to breakthroughs in aerospace materials science and defence technologies.

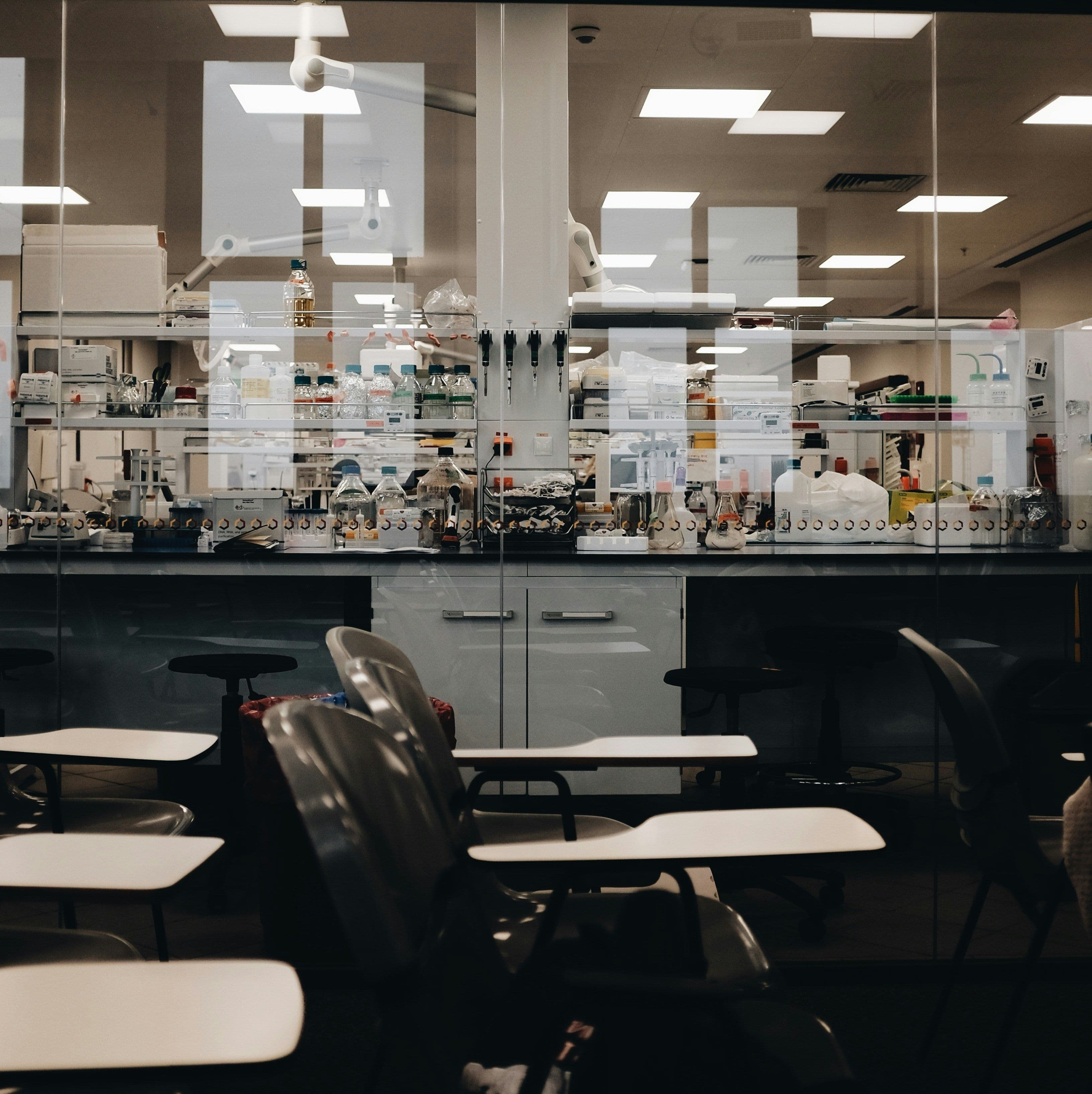

4. Academic & Government Research Labs

Universities and government institutions play a vital role in the early stages of materials and chemical research. Tiltable tubular furnaces provide a versatile solution for controlled experiments in a compact, safe, and efficient package.

In the academic world, they’re used for:

- Educational Demonstrations: In academic settings, these furnaces are ideal for hands-on demonstrations in material science courses, showcasing principles of thermal dynamics, phase changes, and metallurgical processes.

- Innovative Material Research: Government-funded labs often explore sustainable materials and energy solutions. The controlled environment of a tiltable furnace is perfect for studying materials used in solar panels, fuel cells, and energy storage systems.

- Collaborative Projects: With their ease of use and reliability, these furnaces often feature in collaborative research projects that require precise thermal processing across multiple institutions.

Impact on Scientific Progress:

The ease of operation and versatility of tiltable tubular furnaces make them an invaluable tool for fostering innovation and cross-disciplinary research, ultimately enhancing the global knowledge base in various scientific domains.

5. Nuclear Materials & Energy Research

The nuclear industry demands equipment that is not only reliable and efficient but also minimizes the risk of contamination. Tiltable tubular furnaces are designed to work in controlled atmospheres, supporting experiments with radioactive or otherwise hazardous materials.

Key advantages in nuclear applications:

- Fuel Rod Material Development: The ability to safely melt and pour materials facilitates the creation of fuel rod components with improved thermal and mechanical properties.

- Spent Fuel Recycling: Researchers can utilize these furnaces to investigate new methods for recycling spent nuclear fuel, ultimately contributing to more sustainable practices.

- High-Temperature Ceramic Processing: In the field of nuclear energy, advanced ceramics are often used for insulation or containment. The furnace’s precise heating profile ensures the integrity and quality of these critical materials.

Impact on Safety & Efficiency:

By providing a safe, closed system for high-temperature experiments, tiltable tubular furnaces help maintain strict safety protocols while advancing research that underpins the future of nuclear energy technology.

6. Chemical & Petrochemical Processing

Chemical processes such as catalysis, pyrolysis, and calcination require consistent and reliable thermal conditions. In many research and pilot plant setups, tiltable tubular furnaces offer the necessary level of temperature control and direct material handling.

Specialized use cases include:

- Catalyst Synthesis: The furnace can be used to prepare catalyst materials through controlled melting, which improves performance in chemical reactions.

- Pyrolysis Studies: Researchers can conduct pyrolysis experiments by simulating high-temperature conditions that break down complex materials into simpler compounds.

- Salt and Sulfur Treatment: Some chemical processes require melting salts or sulfur compounds in a controlled manner, where the tiltable design minimizes exposure and improves safety.

Impact on Process Optimization:

The combination of precise thermal management and safe pouring features allows the chemical and petrochemical industries to optimize reaction pathways, reduce waste, and improve the efficiency of material synthesis processes.

The tiltable tubular furnace might seem like a niche piece of equipment at first glance, but its versatility and safety features make it a powerhouse in several leading industries. From metallurgy to nuclear energy and chemical processing, these furnaces are integral to fostering innovation and maintaining safe, efficient operations in high-temperature environments.

As industries continue to push the boundaries of science and technology, the role of tiltable tubular furnaces is bound to expand. If your organization is looking to enhance its material processing capabilities or invest in cutting-edge research equipment, consider the benefits of incorporating a tiltable tubular furnace into your workflow.