Jar mills play a crucial role in research and material testing labs, serving as essential equipment for various applications. They are used for grinding, mixing, and blending materials to achieve a uniform particle size distribution. If you're new to this equipment or looking to optimize its use in your lab, understanding its key benefits and learning how to operate it effectively can significantly improve the quality and consistency of your experiments.

In this blog, we’ll cover the key benefits of using a laboratory jar mill in material testing and provide a step-by-step guide to operating the jar mill to help you maximize your grinding efficiency.

5 Key Benefits of Using a Laboratory Jar Mill in Material Testing

- Precise Particle Size Control One of the most important advantages of using a laboratory jar mill is the ability to achieve precise control over particle size distribution. When conducting material testing, particle size is a key factor that influences the properties and behaviour of a substance. Laboratory jar mills allow for consistent and uniform grinding, ensuring that the material is processed to the desired fineness. This is crucial for applications such as materials science, pharmaceuticals, and nanotechnology, where precise particle size influences the outcome of experiments.

- Scalability and Versatility Laboratory jar mills offer exceptional versatility, capable of processing a broad range of materials such as powders, pastes, and slurries. Whether you’re working with hard, brittle materials or softer substances, these mills can be adjusted to suit your needs. Additionally, they are scalable from small batch testing to larger-scale processes, making them a great choice for both preliminary and advanced material testing.

- High Efficiency and Consistency Jar mills offer excellent efficiency and consistency in grinding. The rotating action of the mill ensures that the materials are exposed to the grinding media in a consistent manner, leading to more uniform results across multiple runs. This consistency is vital for obtaining reproducible data in material testing, ensuring that your experiments yield reliable and comparable results.

- Safety and Reduced Contamination Risks Laboratory jar mills are designed with safety in mind, minimizing the risk of contamination during the grinding process. Many models come with sealed containers that prevent the escape of dust and other particles, which is important when dealing with fine materials or hazardous substances. This reduces the chances of cross-contamination and ensures that your tests remain accurate and free from external influences.

- Low Maintenance and Long Lifespan Laboratory jar mills are built for durability and require minimal upkeep. With regular care, they are capable of running smoothly and effectively for an extended period. As a result, they offer excellent value for laboratories that perform grinding tasks regularly. Most models are also simple to clean and maintain, helping ensure your equipment stays in optimal condition over time.

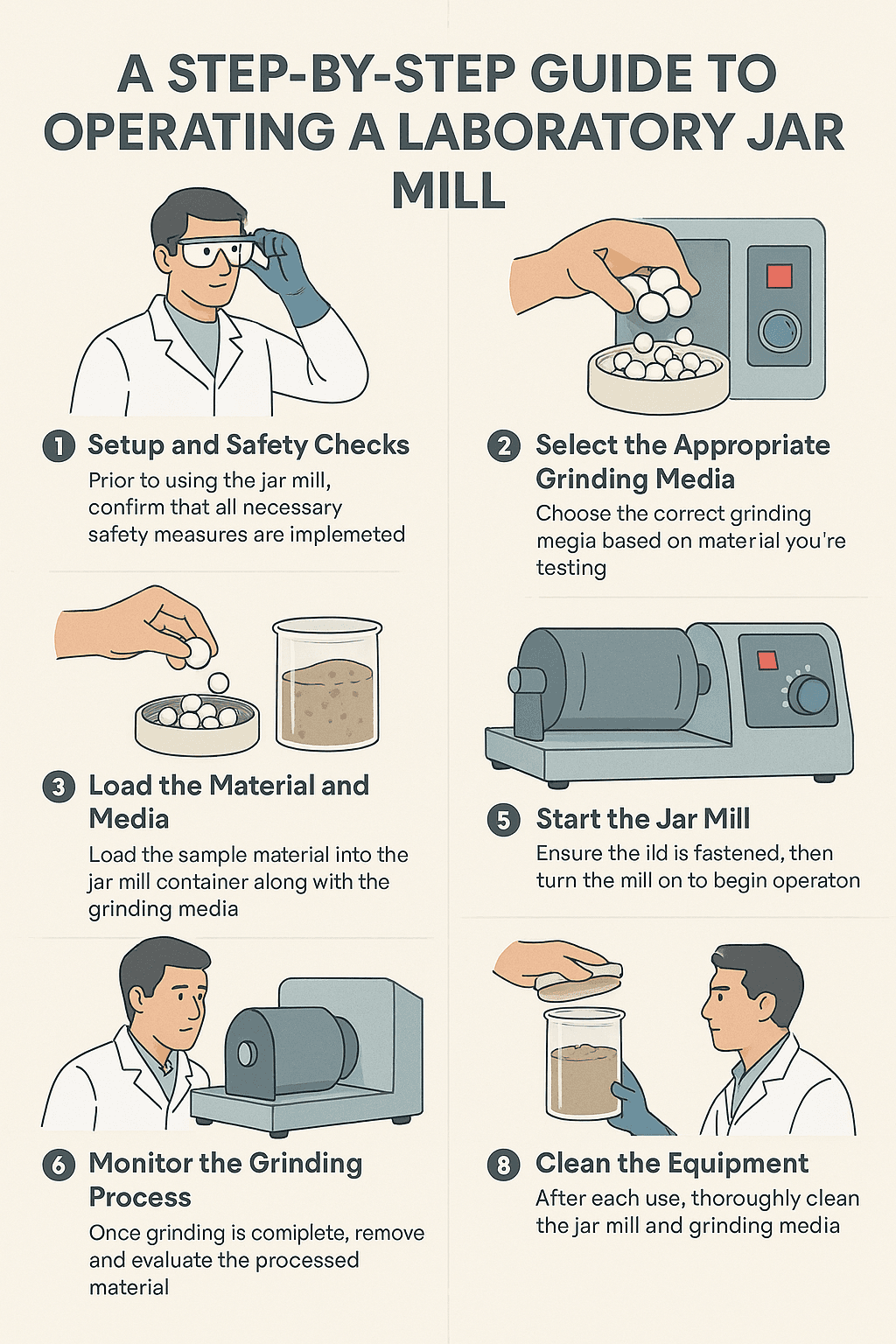

A Step-by-Step Guide to Operating a Laboratory Jar Mill

Now that you understand the benefits of using a laboratory jar mill in material testing, let’s walk through the steps to effectively operate this equipment.

Step 1: Setup and Safety Checks

Prior to using the jar mill, confirm that all necessary safety measures are implemented. This includes wearing suitable personal protective equipment (PPE) like gloves, safety glasses, and a lab coat. Check the mill to ensure it is in good working condition and that all parts are securely fastened. Ensure the power supply is consistent and that the mill is placed on a stable, flat surface to minimize any vibration during operation

Step 2: Select the Appropriate Grinding Media

Select grinding media that are suitable for the type of material being processed. These media are typically composed of materials like steel, ceramic, or zirconia and come in different shapes and sizes, such as spheres and cylinders. The effectiveness of the grinding process and the resulting particle size depend heavily on this choice. Generally, larger media are more efficient for breaking down tougher materials, while smaller ones are ideal for producing finer particles.

Step 3: Load the Material and Media

Load the sample material into the jar mill container, ensuring you don’t overfill it. A common ratio is 25% material to 75% media, but this can vary depending on the specific requirements of your experiment. Make sure the sample and grinding media are uniformly arranged in the container to avoid inconsistent grinding.

Step 4: Set the Speed and Time

Adjust the mill’s speed and timing according to the nature of your material and the desired grind size. Jar mills typically operate at different speeds depending on the material’s hardness and the type of grinding required. The time set for grinding also depends on the material’s characteristics and the degree of fineness needed. Start with the manufacturer’s recommended settings and adjust as needed for optimal results.

Step 5: Start the Jar Mill

Once you’ve loaded the material, media, and set the appropriate grinding parameters, start the jar mill. Ensure the lid is tightly closed to avoid any material leakage while the machine is running. Keep an eye on the mill throughout the operation to ensure it runs smoothly and without issues. Most jar mills have built-in safety features that automatically stop if there is an issue, but it’s important to always remain vigilant.

Step 6: Monitor the Grinding Process

While the mill is running, monitor the material for any changes in consistency or appearance. If needed, you can pause the process to check the progress and adjust the speed, time, or media. It’s important to avoid over-grinding, which can result in excessive wear on the equipment and unnecessary material degradation.

Step 7: Unload and Inspect the Material

After finishing the grinding cycle, power off the mill and gently take out the jar. Open it to inspect the material and check if the particle size is uniform. Depending on the results, you may need to continue grinding or adjust the settings for the next round.

Step 8: Clean the Equipment

After each use, it's important to clean the jar mill and grinding media carefully to avoid cross-contamination and maintain consistent results in subsequent tests. Use manufacturer-approved cleaning agents and techniques to ensure safe, effective maintenance. Keeping the equipment clean not only supports reliable testing but also helps prolong its operational life.

Using a laboratory jar mill in material testing offers numerous benefits, including precise particle size control, versatility, and high efficiency. By following the step-by-step guide outlined in this blog, you can operate your jar mill with confidence, ensuring consistent, reliable results in your material testing experiments. Proper operation and maintenance of this equipment will help maximize its lifespan, making it a valuable asset for your laboratory for years to come.

With its ease of use and ability to scale to various applications, the laboratory jar mill is a critical piece of equipment for researchers and scientists looking to achieve accurate and reproducible data.