Precision and reliability are paramount in metallurgy. The properties of metals and alloys form the backbone of countless products and systems, from aerospace components to automotive parts and construction materials. To ensure these materials meet stringent industry standards, metallurgical testing plays a critical role. Laboratory furnaces are indispensable tools in this domain, significantly contributing to testing processes that evaluate material integrity, durability, and performance.

The Role of Metallurgical Testing

Metallurgical testing focuses on evaluating the physical and chemical properties of metals and alloys, including strength, hardness, toughness, corrosion resistance, and microstructure. Accurate testing is essential for:

- Quality Control: Ensuring materials meet specifications for their intended applications

- Failure Analysis: Identifying the causes of material defects or breakdowns

- Research and Development: Creating new materials and enhancing existing ones

- Regulatory Compliance: Adhering to industry standards and certifications

Laboratory Furnaces: The Backbone of Metallurgical Testing

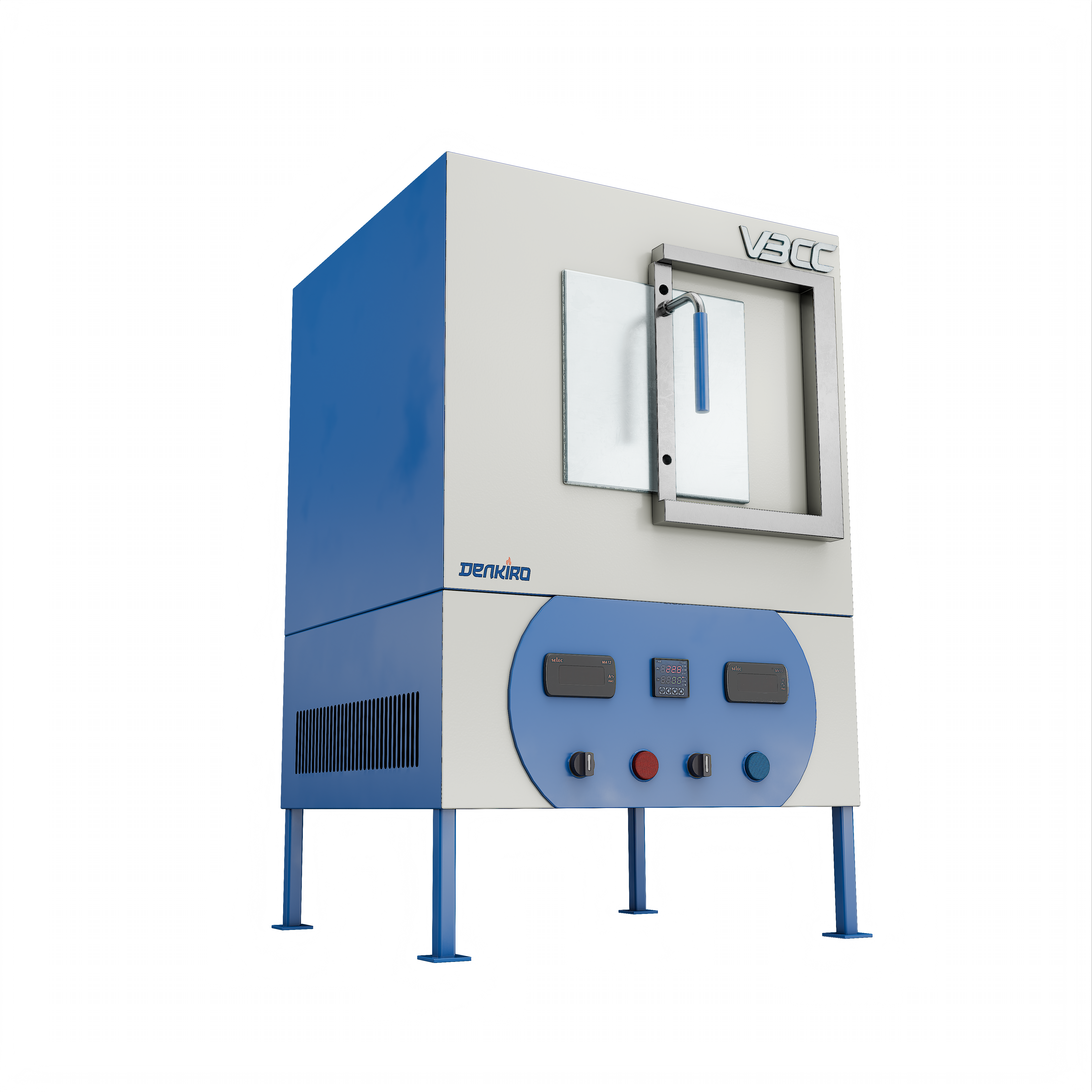

Laboratory furnaces are at the core of many metallurgical testing processes. These high-temperature instruments enable controlled heating, a critical requirement for analysing and modifying the properties of metals. Their contributions include:

Heat Treatment Testing

Processes like annealing, quenching, and tempering modify a material’s mechanical properties. Laboratory furnaces provide precise temperature control, ensuring consistent heating and cooling cycles essential for:

- Enhancing hardness and strength

- Improving ductility

- Relieving internal stresses

Sintering and Melting

Sintering consolidates powdered metals into solid materials, while melting tests reveal a material’s thermal behaviour and purity. Laboratory furnaces deliver the high temperatures required for these processes, ensuring uniform results.

Thermal Analysis

Techniques such as differential thermal analysis (DTA) and thermogravimetric analysis (TGA) depend on laboratory furnaces to assess a material’s response to temperature changes. These tests provide valuable data on phase transitions, oxidation resistance, and thermal stability.

Microstructure Examination

Heat treatments performed in furnaces prepare samples for metallographic analysis. Controlled heating and cooling conditions allow researchers to study grain structures, phase distributions, and other microstructural features.

Benefits of Modern Laboratory Furnaces

Advancements in furnace technology have improved their reliability and versatility, offering features that make them indispensable in metallurgy and powder metallurgy testing:

- Accurate Temperature Regulation: Delivers consistent and reliable results

- Uniform Heat Distribution: Prevents localized discrepancies across samples

- Programmable Operations: Automates temperature cycling, improving efficiency and accuracy

- Energy Efficiency: Innovative insulation and heating elements reduce energy consumption

Applications Across Industries

Metallurgical testing supported by laboratory furnaces serves a wide range of industries:

- Aerospace: Verifying the performance of advanced alloys used in engines and airframes.

- Automotive: Testing steel and aluminium components for strength and durability.

- Construction: Validating the integrity of structural materials.

- Manufacturing: Assessing raw materials used in machinery and tools.

- Powder Metallurgy: Optimizing sintering and bonding processes for metal powders.

Advancing Metallurgical Innovation

In metallurgy, where material integrity directly impacts performance and safety, laboratory furnaces are indispensable. These high-temperature instruments support vital testing processes to ensure metals and alloys meet the most rigorous standards. Whether in furnace metallurgy, powder metallurgy, or welding metallurgy, laboratory furnaces provide the precision and reliability needed to advance material science.

As industries demand stronger and more reliable materials, laboratory furnaces will remain at the forefront of metallurgical innovation, driving progress and ensuring quality. Investing in advanced furnaces is critical for achieving exceptional accuracy and dependability in metallurgical testing.