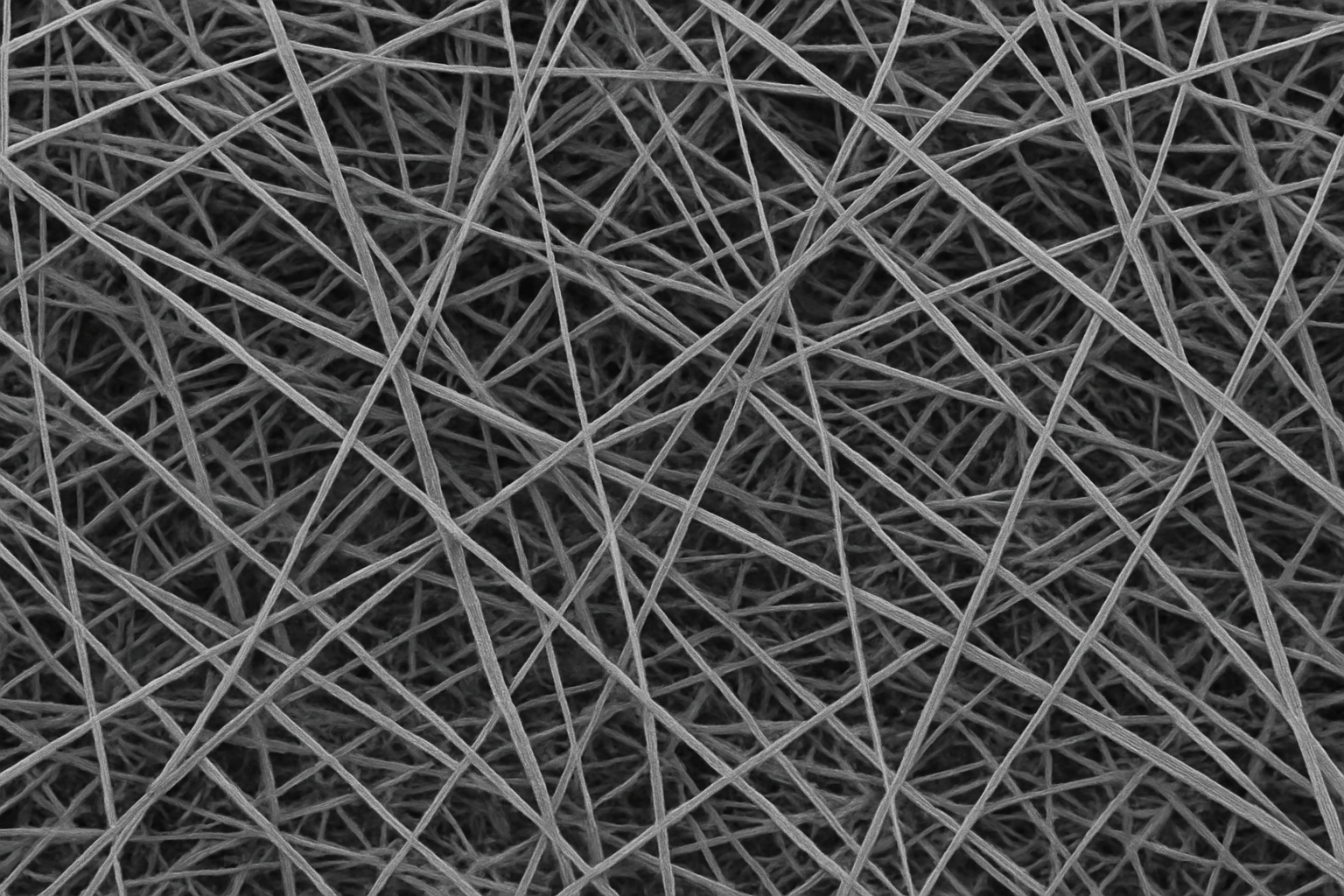

Electrospinning has transformed the way we produce nanofibers for applications ranging from biomedical scaffolds to high-efficiency filters. But with a growing range of Electrospinning Machine options available, selecting the right one can feel overwhelming—especially when your choice directly affects fibre quality, throughput, and project success.

This guide breaks down the critical factors to consider whether you’re equipping a small research lab or scaling up for industrial production.

1. Understand Your Application First

Before diving into technical specifications, clarify what you’ll use the Electrospinning Machine for. Your application will determine almost every decision down the line.

- Biomedical research → You’ll need precise control over parameters and possibly sterile enclosures.

- Filtration materials → Throughput and fibre diameter uniformity become a priority.

- Wearable electronics → You might require coaxial or multi-fluid electrospinning capabilities.

- Drug delivery systems → Fine control of fibre morphology and solvent compatibility is key.

Tip: Create a short requirement list before speaking to any Electrospinning Machine supplier.

2. Lab-Scale vs. Industrial-Scale Electrospinning Machines

Lab-Scale Electrospinning Machines

Primarily intended for research and development, these systems emphasize flexibility, modularity, and precise control over processing parameters rather than maximizing output. They often allow interchangeable collectors, multiple spinneret options, and customized experimental setups.

- Produces limited quantities, making it suitable for experimental work and small-scale batches

- Highly adjustable settings for different polymers and fibre morphologies

- Compact size suitable for limited lab space

- Lower upfront cost compared to industrial unit

Industrial-Scale Electrospinning Machines

Engineered for continuous operation and large-volume manufacturing, these systems often incorporate multiple nozzles, conveyor-based collectors, and automated process control for consistent results.

- High production capacity for large-scale applications

- Moderate adjustability, optimized for stability and repeatability

- Requires substantial floor space for installation

- Higher initial investment, designed for high-throughput output

3. Critical Technical Specifications

When investing in an Electrospinning Machine, understanding its technical capabilities is essential. These specifications determine not only the quality and uniformity of the fibres produced but also the flexibility, safety, and scalability of your setup. Let’s break them down:

a) Voltage Range

- Purpose: Voltage is the driving force that creates the electrostatic field necessary to draw fibres from the polymer solution.

- Typical Range: Most lab-scale machines operate between 0–30 kV, which is sufficient for a wide variety of polymers and solvents. Industrial systems may go beyond this range for specialized applications.

- Why It Matters: Too low a voltage may prevent fibre formation, while too high a voltage can cause bead formation, fibre breakage, or unsafe discharges.

- Pro Tip : In regions with fluctuating power supply, machines with in-built voltage stabilizers or UPS backup are advisable for consistent results.

b) Flow Rate Control

- Purpose: Determines how much polymer solution is delivered to the spinneret per unit of time.

- Precision Levels: High-quality syringe pumps with microliter-per-minute accuracy ensure consistent fibre diameter and morphology.

- Why It Matters: An unstable flow rate can lead to bead defects, inconsistent fibre thickness, or even clogging of the needle.

- Advanced Option: Some high-end machines allow multi-channel pumping for simultaneous production of different fibre types.

c) Spinneret Configurations

- Single-Needle Spinnerets: Best for research and applications requiring small-scale, precise control.

- Multi-Needle Systems: Increase throughput by producing fibres from multiple points simultaneously—ideal for pre-commercial production.

- Needleless Electrospinning: Uses a charged surface instead of needles to increase production volume and reduce clogging issues.

- Coaxial Spinnerets: Enable the production of core–shell fibres for applications such as controlled drug release or protective coatings.

- Tri-axial and Multi-fluid Setups: Useful for advanced materials research where multiple layers or functionalities are required in a single fibre.

d) Collector Type

- Flat Plate Collectors: Produce randomly oriented fibre mats, suitable for filtration membranes and wound dressings.

- Rotating Drum/Mandrel Collectors: Create aligned fibres, beneficial for tissue engineering scaffolds or applications requiring directional mechanical strength.

- 3D Collectors: Allow the deposition of fibres onto complex geometries for customized structures.

- Belt/Conveyor Collectors: Enable continuous fibre sheet production in industrial settings.

- Why It Matters: The collector design directly impacts fibre alignment, density, and thickness uniformity.

e) Environmental Control

- Purpose: Environmental temperature and humidity directly influence the structure and quality of fibres

- Humidity: Too high can cause bead formation and fibre fusion; too low may lead to brittle fibres.

- Temperature: Controls solvent evaporation rate, influencing fibre smoothness and diameter.

- Closed-Chamber Systems: Allow for precise environmental regulation, essential for reproducibility.

- Indian Lab Consideration: In regions with tropical or monsoon climates, managing humidity is essential to maintain consistent electrospinning results.

f) Automation & Process Monitoring (Optional but valuable)

- Digital Controls: Touchscreen panels for adjusting and monitoring voltage, flow rate, and collector speed in real-time.

- Data Logging: Stores parameter settings and fibre production data for quality assurance.

- Sensors: Can monitor solution viscosity, droplet formation, and even fibre diameter during operation.

4. Safety Features You Shouldn’t Overlook

Operating an Electrospinning Machine involves high voltage, solvents, and fine particulates. Look for:

- Enclosed cabinet with interlocks.

- Proper grounding and shielding.

- Solvent fume extraction or HEPA filtration.

- Emergency stop buttons within reach.

5. User Interface and Automation

Modern Electrospinning Machines offer touchscreen control, recipe storage, and data logging.

- Beginner-friendly → Offers user-friendly presets and visual controls for adjusting parameters.

- Advanced research → Fine-grained control, integration with external sensors, and programmable sequences.

6. Budget, Maintenance, and Support

- Initial Cost → In India, entry-level lab-scale Electrospinning Machines typically start from around ₹8–12 lakhs, while advanced research models range from ₹15–25 lakhs. Industrial-scale systems can go upwards of ₹80 lakhs to ₹1.5 crore, depending on customization, throughput, and automation features.

- Maintenance → Annual service agreements, often priced at 5–8% of the machine’s value, are typical. Routine upkeep may involve calibration, replacing spinneret needles, cleaning collectors, and maintaining the environmental chamber.

- After-Sales Support → Many suppliers in India offer local service teams in metro cities like Bengaluru, Pune, Delhi, and Hyderabad. Availability of spare parts within India is crucial to avoid import delays. Some manufacturers also provide remote troubleshooting, operator training, and quick turnaround repairs to reduce downtime.

7. Request a Demo or Sample

Before committing to an Electrospinning Machine:

- Ask for a sample run using your own polymer solution.

- Evaluate fibre uniformity, reproducibility, and ease of operation.

- Check how easy it is to switch between setups or clean the machine.

Choosing the right Electrospinning Machine isn’t just about specs—it’s about matching the tool to your workflow, materials, and goals. By defining your application, understanding key technical features, and assessing safety, scalability, and support, you can invest with confidence and set your project up for success.