Preserving ancient artifacts is crucial to understanding human history and culture. Over time, objects made of organic and inorganic materials, such as metals, ceramics, and stones, degrade due to environmental factors like humidity, temperature, and light. To maintain the integrity of these precious items, scientists and conservators employ specialized tools and techniques, one of the most important being laboratory furnaces. These high-tech devices play a vital role in preserving, analysing, and restoring artifacts, ensuring that they continue to provide valuable insights for generations to come.

The Role of Laboratory Furnaces in Artifact Preservation

Laboratory furnaces are essential tools used to subject artifacts to controlled heating processes, often at extremely high temperatures. These processes serve various purposes, such as cleaning, stabilizing, and reconstructing ancient objects. Here are how laboratory furnaces contribute to artifact preservation:

1. Degreasing and Cleaning Artifacts

Artifacts, especially those from ancient times, often accumulate dirt, oils, and residues over centuries. These materials can obscure the object’s true value and cause further deterioration. Laboratory furnaces, equipped with precise temperature controls, can safely remove contaminants without damaging the underlying material.

For example, ceramic artifacts can be gently heated in a furnace to remove organic residues. The controlled environment prevents the objects from cracking or warping, ensuring that the cleaning process enhances rather than harms the artifact.

2. Stabilizing Materials

Over time, materials such as metals, glass, and ceramics can become brittle, corroded, or unstable. Furnaces are used to stabilize these materials by treating them in a controlled heat environment. For example, metals like iron and bronze can be heat-treated to prevent rust and corrosion. This process not only preserves the artifact’s structural integrity but also enhances its longevity.

3. Sintering and Reforging

Ancient objects that have been broken or fractured over time can be reforged in laboratory furnaces. Through sintering or re-melting techniques, the furnace helps bond broken pieces together without compromising the object’s authenticity. This process is particularly important when working with metals or ceramics, where even slight changes in temperature or handling can result in permanent damage. Laboratory furnaces offer a precise and controlled atmosphere to ensure that the repair is both effective and safe.

4. Heat Treatment for Deacidification

Some artifacts, particularly those made from paper, textiles, and other organic materials, are vulnerable to acidity, which can cause degradation. Laboratory furnaces can be used for controlled heat treatments that help deacidify these materials, neutralizing harmful acidic compounds and extending their lifespan. This process is critical for preserving ancient manuscripts, paintings, and textiles for future study.

5. Analysing Composition and Structure

Furnaces are also invaluable in the scientific analysis of ancient artifacts. By exposing small samples to high temperatures in a laboratory furnace, scientists can analyze the chemical and physical properties of the materials. This process can reveal details about the object’s composition, origin, and the techniques used to create it, providing vital information for historians and archaeologists.

Types of Laboratory Furnaces Used in Artifact Preservation

Choosing the right furnace for artifact preservation is crucial, as different furnaces are designed for specific applications. Some common types include:

1. Microwave Furnaces

These furnaces provide rapid and uniform heating, making them ideal for high-temperature synthesis or sintering of certain materials without causing thermal stress. They are often used for cleaning delicate materials and ensuring uniform heating.

2. Roller Hearth Furnaces

Designed for gradual and controlled heat treatment, these furnaces are suitable for stabilizing fragile artifacts. They ensure precise temperature management, which is essential for treating brittle materials like glass and ceramics.

3. Atmosphere-Controlled Furnaces

These furnaces maintain a controlled atmosphere, ensuring no unwanted gases or elements affect the object during heating. They are especially useful for preserving metals and other sensitive materials prone to oxidation or chemical reactions.

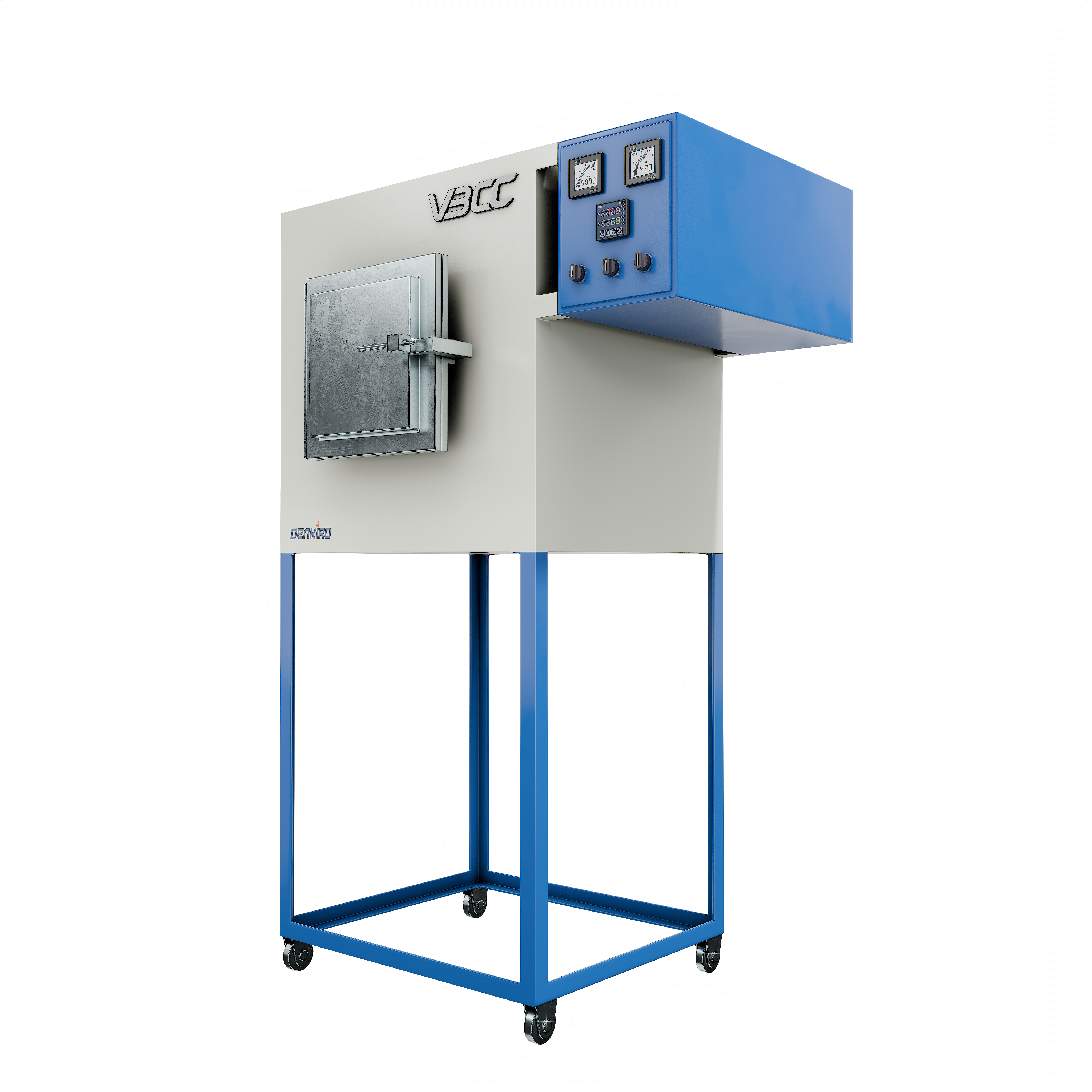

4. Vacuum Furnaces

Vacuum furnaces are used to process materials in a low-pressure environment, preventing contamination and oxidation. These furnaces are ideal for delicate artifacts that require careful handling and treatment.

5. High-Temperature Furnaces

Capable of reaching extremely high temperatures, these furnaces are used for sintering and reforging processes, making them indispensable for repairing and reconstructing metal and ceramic artifacts.

Laboratory furnaces are indispensable tools in the field of artifact preservation. By allowing conservators and scientists to carefully heat and treat materials, these furnaces help restore and stabilize ancient objects, preserving them for future generations. Whether used for cleaning, stabilization, or analysis, laboratory furnaces ensure that the treasures of the past continue to enlighten us about the cultures and civilizations that came before us.