A hydraulic press is a powerful mechanical device that uses hydraulic force to compress, shape, or mold materials. It plays a crucial role in various industries, including metalworking, automotive manufacturing, and even scientific research. Let’s see exactly how a hydraulic press works by breaking it down.

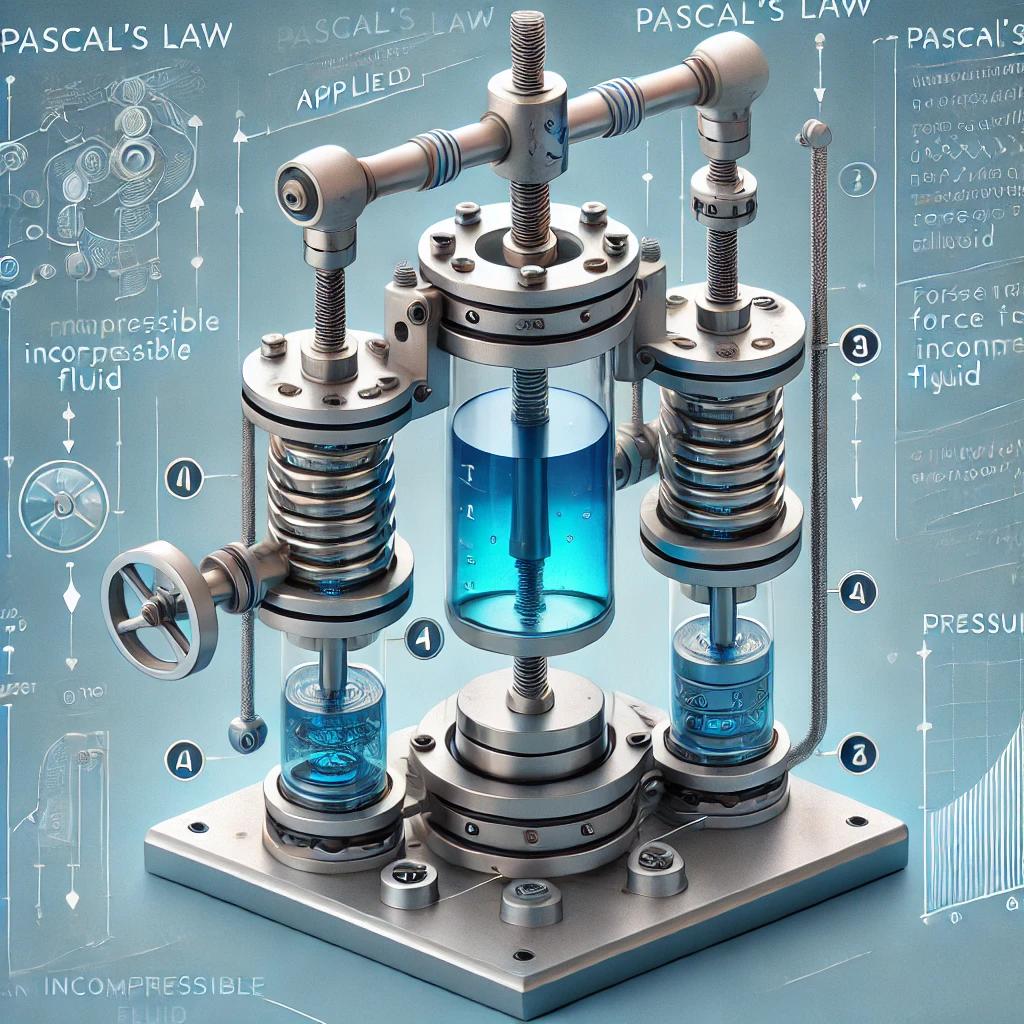

The Basic Principle: Pascal's Law

The fundamental working principle of a hydraulic press is based on Pascal's Law. This law states that when pressure is applied to a confined fluid, the pressure is transmitted equally in all directions. In simple terms, a small force applied to a small area results in a much larger force on a bigger area, making hydraulic presses incredibly efficient and powerful.

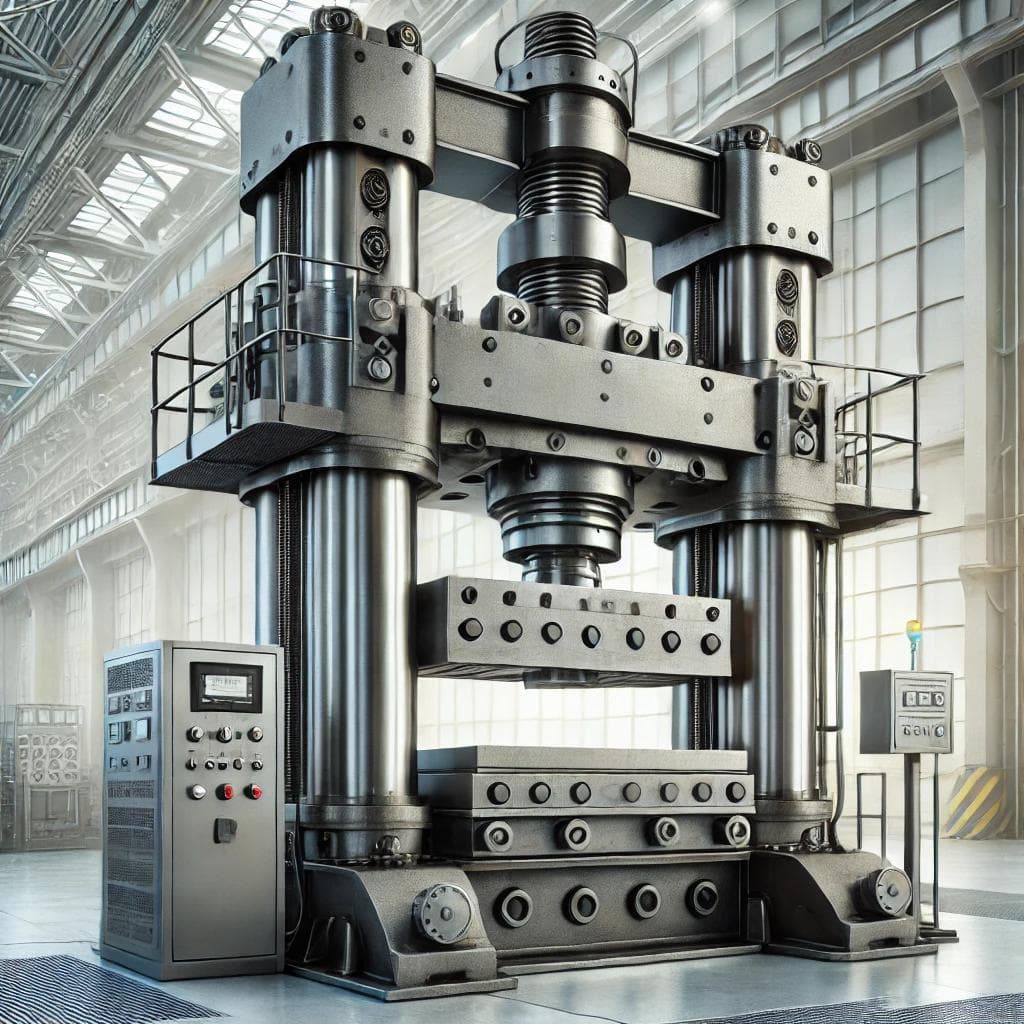

Key Components of a Hydraulic Press

A hydraulic press consists of several key components that work together to generate immense force. These include:

1. Hydraulic Cylinder

The hydraulic cylinder is the main component where hydraulic fluid applies pressure to a piston, creating force. There are usually two cylinders in a press: a master cylinder (smaller) and a slave cylinder (larger), which helps in force multiplication.

2. Hydraulic Fluid

Special hydraulic oil or fluid is used to transmit force within the system. This fluid is non-compressible and flows through the press to create the necessary pressure.

3. Pump

A hydraulic pump generates the required pressure by forcing fluid into the system. It can be powered manually, electrically, or pneumatically, depending on the press type.

4. Valves

Valves control the flow of hydraulic fluid, allowing pressure to build up and be released as needed. Directional valves help regulate movement, while pressure-relief valves prevent overloading.

5. Frame & Platen

The frame provides structural support, while the platen is the flat surface that presses against the material being compressed. These components must be strong enough to withstand extreme pressure.

How the Hydraulic Press Works – Step by Step

Applying Force to the Master Cylinder

- The system is activated, and hydraulic fluid is pumped into the master cylinder.

Force Transmission

- The fluid transfers pressure through the hydraulic lines to the larger slave cylinder.

Force Amplification

- Since the slave cylinder has a larger surface area, it generates a much greater force than the input applied to the master cylinder.

Compression and Pressing

- The platen moves downward, applying high pressure to the material placed on the press bed.

Releasing Pressure

- Once the process is complete, the hydraulic valves release the fluid, allowing the press to reset for the next operation.

Automatic vs. Manual Hydraulic Press Machines

Automatic Hydraulic Press Machine

Automatic hydraulic presses are equipped with programmable logic controllers (PLC) and sensors that automate the pressing process. These machines require minimal human intervention and can handle high-volume production with precise control. The key benefits of automatic hydraulic presses include:

- Increased efficiency and consistency

- Programmable pressure and speed settings

- Reduced labour requirements

- Enhanced safety features

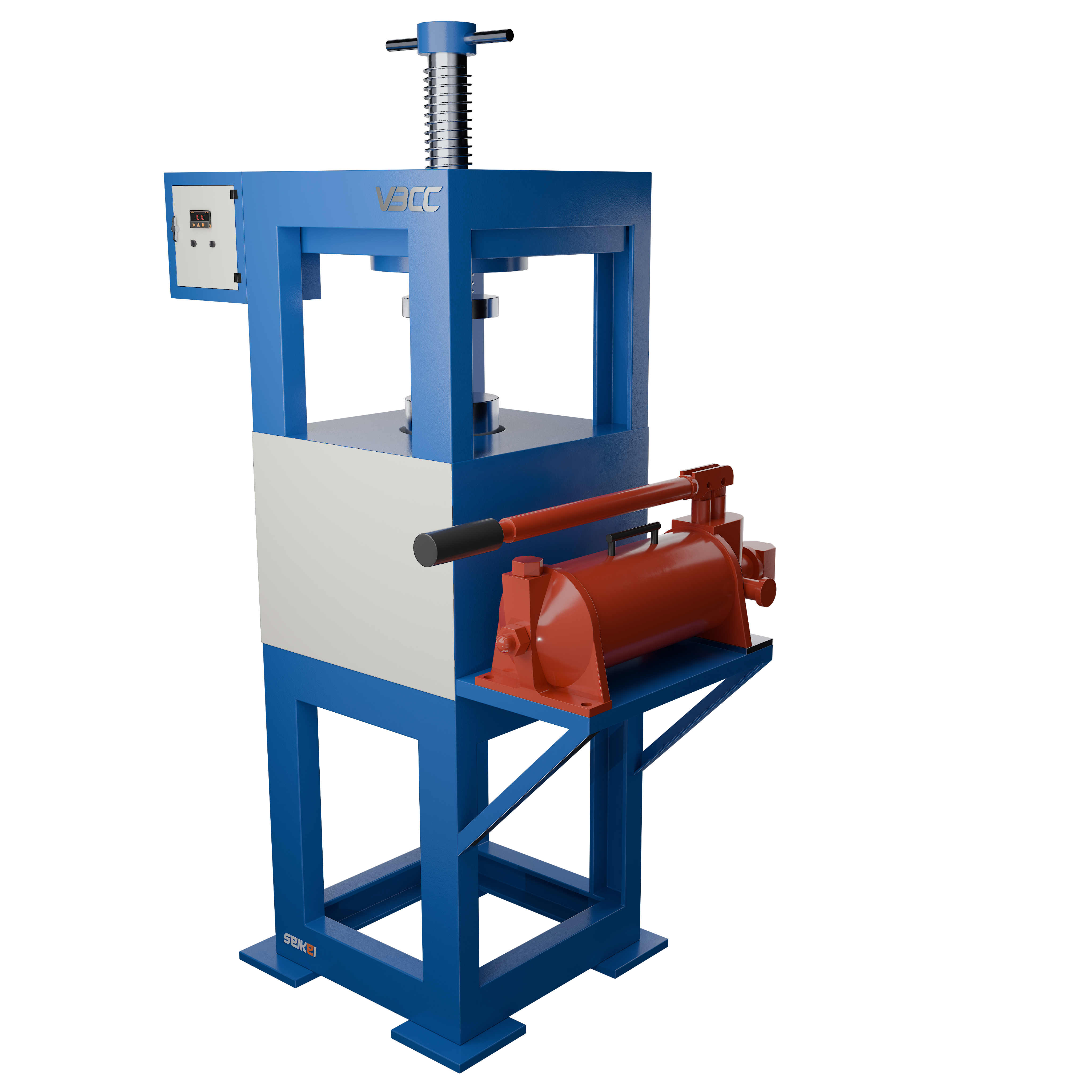

Manual Hydraulic Press Machine

Manual hydraulic presses require human effort to operate the pump and control the pressure applied to the material. These machines are commonly used for small-scale applications and workshops where automation is not necessary. The advantages of manual hydraulic presses include:

- Cost-effectiveness

- Simple operation and maintenance

- Ideal for low-volume tasks

- Greater control over the pressing process

Applications of Hydraulic Presses

Hydraulic presses are used in various industries for different purposes, such as:

- Metal Forming & Stamping: Shaping metals for automotive and aerospace components

- Plastic & Rubber Molding: Creating molded parts for industrial use

- Recycling & Waste Management: Compacting waste materials like scrap metal and paper

- Automotive Repair: Pressing bearings and other components into place

- Scientific Research: Testing material strength under extreme pressure

A hydraulic press is an incredible machine that leverages Pascal's Law to generate immense force with minimal effort. Its efficiency, versatility, and power make it an essential tool in various industries. Whether you're working in manufacturing, recycling, or scientific research, understanding how a hydraulic press works can help you make the most of this powerful technology.