This website is under development

Two or Three zone Furnace

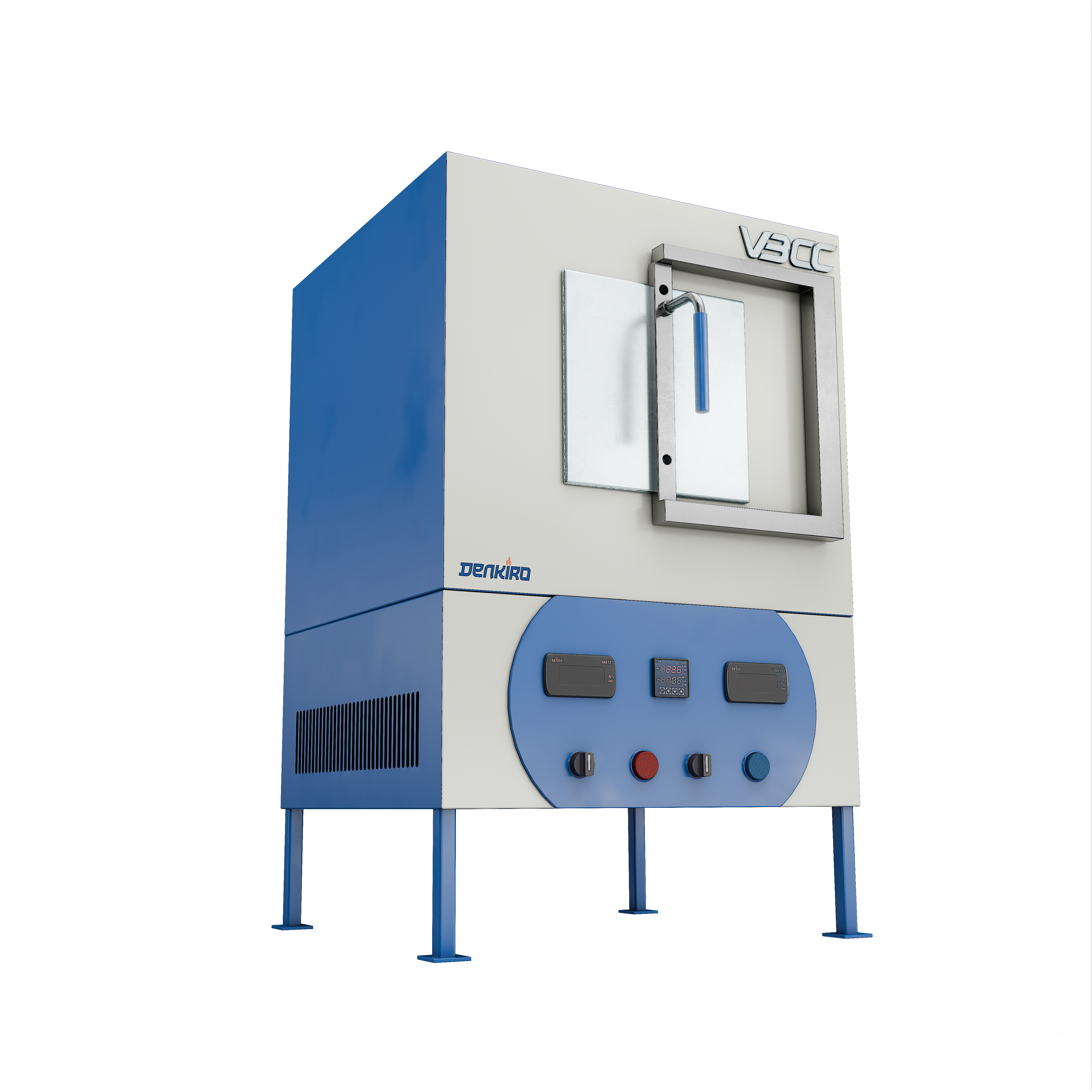

Denkiro is the dedicated sub-brand for electric furnaces under VBCC, embodying precision, efficiency, and innovation in thermal processing. Denkiro electric furnaces are designed to meet the high demands of various industries, offering reliable performance and cutting-edge technology.

- Advanced Three-Zone Design :Engineered with three independent heating zones, providing precise temperature control and versatility for diverse heating profiles.

- Optimized Shell Size :Compact shell size maximizing laboratory space utilization while accommodating ample sample volume.

- Durable Construction :Built with robust MS body and angle structures, reinforced with stiffeners, ensuring stability and durability for long-term operation.

- High-Temperature Tubular Material :Utilizes 99.9% alumina tubes capable of withstanding temperatures up to 1800°C, ensuring durability and reliability under extreme conditions.

- Precise Gas Control :Equipped with stainless steel fittings and O-ring seals for controlled atmosphere operations, facilitating vacuum and multi-gas purging.

- Advanced Heating System :Employs molybdenum disilicide rods (Super Kanthal-1800°C) in U-shape configuration for each zone, providing rapid and uniform heating up to 1800°C.

- Flexible Power Requirements :Operates on 415V, 2-phase, 15A with power isolation transformer, delivering approximately 50V / 200A AC to each element.

- Customizable Temperature Control :Features TAIE PIO- 18*8=144 Segments programmers with R-type thermocouples for precise temperature control and ±1°C accuracy.

- Temperature Monitoring :Includes hand-held sample temperature measurement and control.

- Efficient Vacuum System :Achieves a vacuum level of 760Hg with a rotary-type vacuum pump, ensuring reliable evacuation for precise processing.

- Gas Purging Arrangement :Utilizes SS 304 pipelines and standard valves for gas flow control, complemented by rotameters or Mass Flow Controller for accurate gas purging.

- Enhanced Cooling System :Equipped with a 50-liter water chilling unit with automatic temperature control, ensuring optimal cooling for vacuum and purging processes.

- Convenient Mobility :Designed with wheel-mounted water chilling plant for easy equipment relocation and independent control switches for enhanced flexibility.

- Reliable Performance :Engineered for continuous operation at high temperatures, delivering consistent and reproducible results for various research and industrial applications.

More Dental Furnaces

Box Furnace/ Muffle Furnace