This website is under development

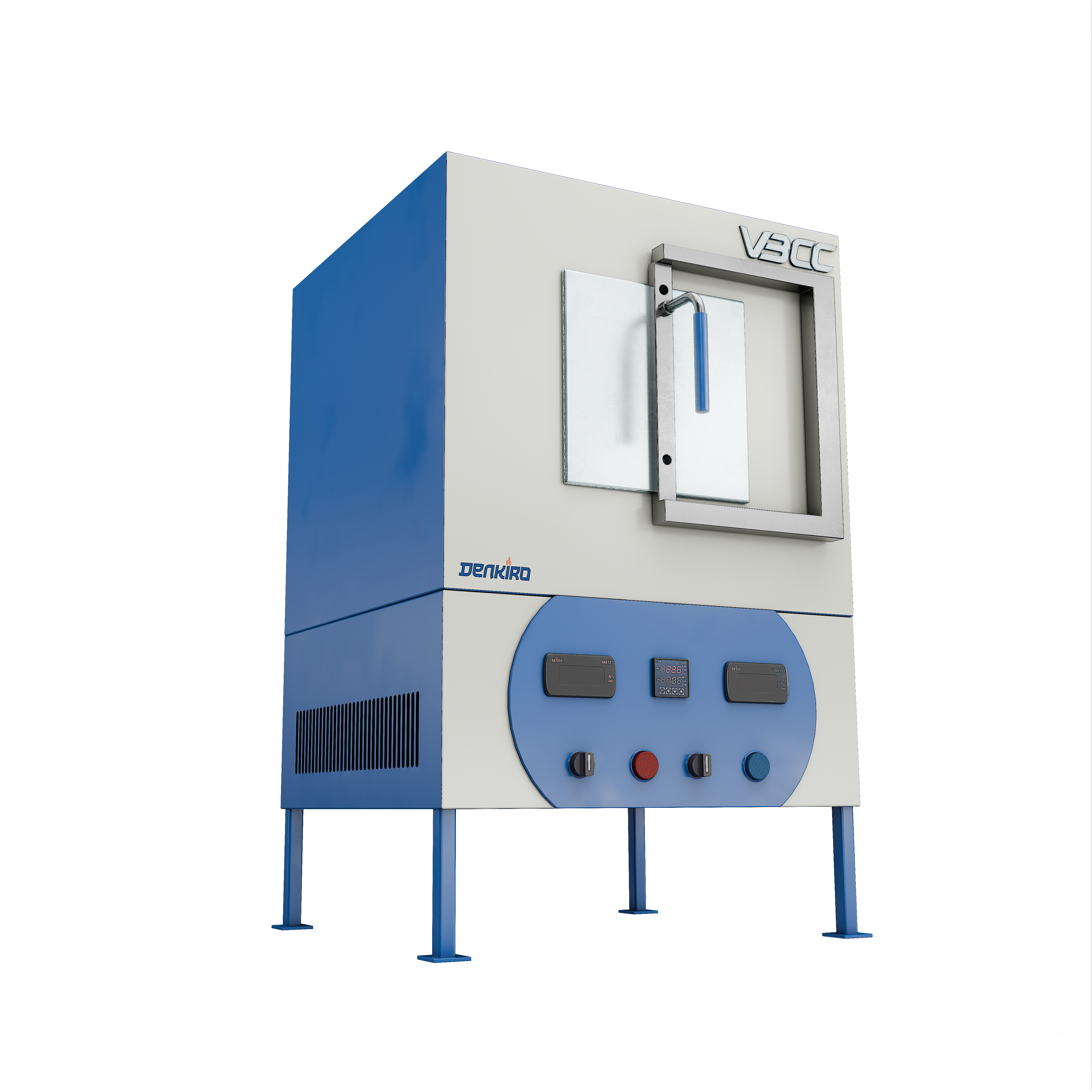

Thermal Cycling Furnace

Denkiro is the dedicated sub-brand for electric furnaces under VBCC, embodying precision, efficiency, and innovation in thermal processing. Denkiro electric furnaces are designed to meet the high demands of various industries, offering reliable performance and cutting-edge technology.

- Extreme Temperature Capability :The Thermal Cycle furnace is engineered to reach temperatures up to 1600 degrees Celsius, empowering precise thermal cycling and material processing in demanding applications.

- Versatile Single Chamber Design :Dimensions according to customer requirement, the single chamber configuration offers versatility for a wide range of heating and processing tasks.

- Precise Temperature Control :Featuring a sophisticated TAIE PID-18*8=144 Segments programmer and digital temperature controller, the Thermal Cycle ensures precise temperature regulation with an accuracy of 1°C, even at extreme temperatures.

- Robust Construction :Crafted with a double-wall MS body and angle structure, fortified with proper stiffeners and powder coat painting, the Thermal Cycle guarantees durability and sustained performance under high-temperature conditions.

- Efficient Insulation :Utilizing high-quality alumina bricks and mechanically pressed fiber blanket insulation, this furnace maintains uniform temperatures and minimizes heat loss, ensuring consistent and reliable operation during thermal cycling.

- Enhanced Door Design :Equipped with a stainless steel door featuring proper insulation to mitigate heat loss, the Thermal Cycle ensures energy efficiency and stable operation throughout the thermal cycling process.

- Convenient Sample Loading :The furnace accommodates sample loading with ease, utilizing a sample holder placed at the bottom of the furnace door, fully lined with mullite blocks for effortless loading and unloading.

- Integrated Compressor :With an inbuilt compressor boasting a maximum pressure of 6kg/cm², the Thermal Cycle supports pneumatic cylinders for smooth and reliable door movement during thermal cycling operations.

- PLC-Based Automation :Leveraging PLC-based operation, the Thermal Cycle offers automated control and seamless integration with other system components, enabling precise control and monitoring even under extreme temperature conditions.

- High-Performance Heating Elements :Incorporating eight solid-type silicon carbide heating elements imported from ISQUARED R, USA, the Thermal Cycle delivers efficient heating up to 1600 degrees Celsius, crucial for high-temperature thermal cycling processes.

- Flexible Power Requirements :Operating on 415V AC with a total power of 4kW, the Thermal Cycle ensures ample power supply to maintain high temperatures consistently and reliably.

- Intuitive Control Panel :The control panel features indicators for ammeter, mains, and output, along with control switches, offering intuitive operation and control over the thermal cycling process.

- Streamlined Process Automation :Through PLC integration with Omron/Fuji or equivalent HMI, the Thermal Cycle enables streamlined process automation and control, enhancing efficiency and productivity in thermal cycling applications.

- Robust PLC Configuration :With 8 input and output points featuring photo-coupler insulation, the PLC ensures reliable operation and data transmission, critical for maintaining process stability during thermal cycling.

- User-Friendly Interface :The 7" wide HMI boasts a TFT color display, touch screen operation, and RS-232C communication, providing a user-friendly interface for easy monitoring and control.

More Dental Furnaces

Box Furnace/ Muffle Furnace