This website is under development

Rotary Tubular Furnace

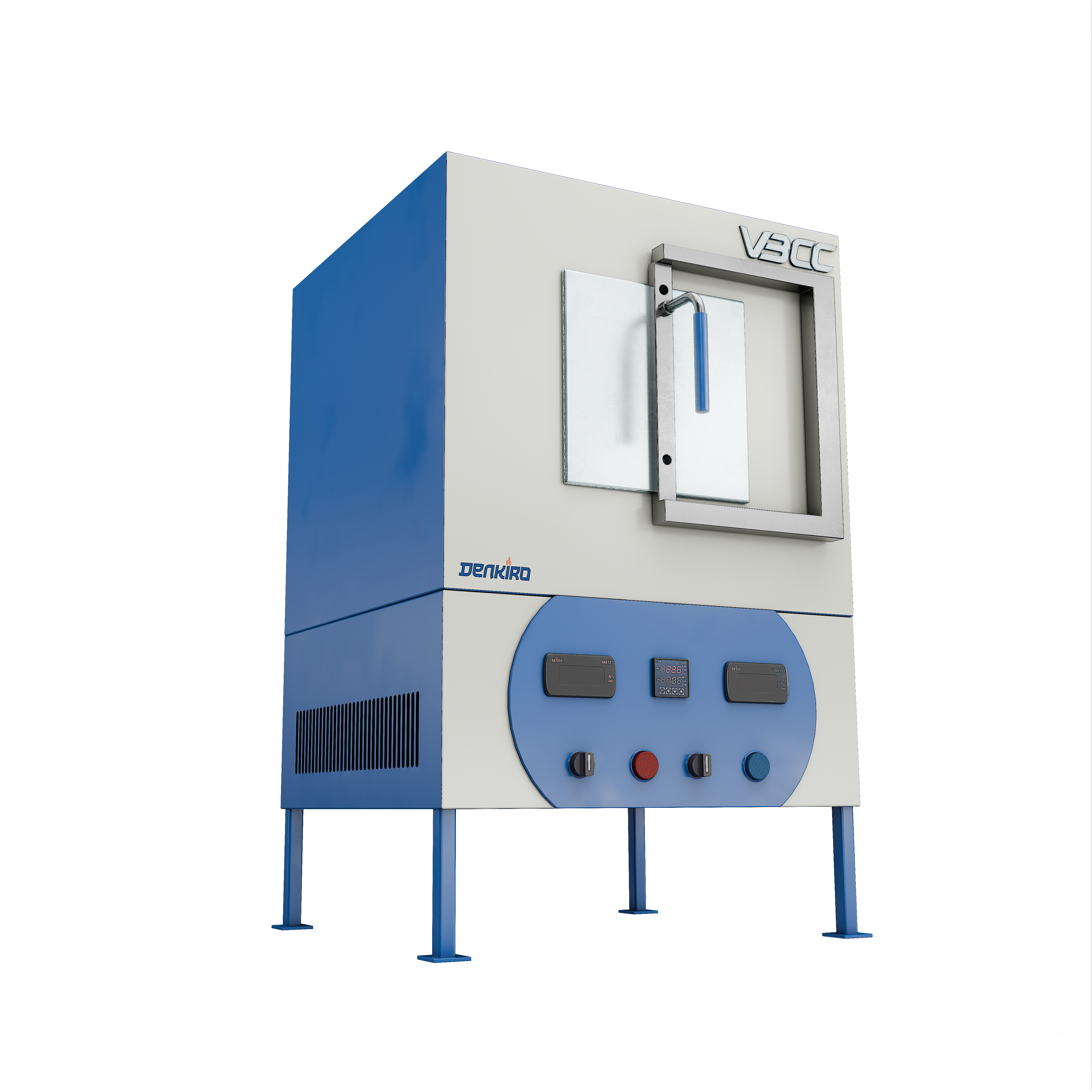

Denkiro is the dedicated sub-brand for electric furnaces under VBCC, embodying precision, efficiency, and innovation in thermal processing. Denkiro electric furnaces are designed to meet the high demands of various industries, offering reliable performance and cutting-edge technology.

- Temperature Uniformity :Equipped with strategically placed heating elements to achieve exceptional uniformity of ±5°C across the entire working zone, critical for consistent results.

- Robust Construction :Stainless steel body and angle structure with stiffeners ensure durability and stability, while powder coat painting enhances aesthetics and corrosion resistance.

- Precise Temperature Control :TAIE microprocessor-based PID controller- 18*8=144 Segments offers precise temperature regulation with an accuracy of ±1°C, maintaining optimal conditions for your process.

- Efficient Heating System :Features APM Kanthal heating element, delivering reliable heating performance up to 1200°C for continuous operation. For 1400°C it is Silicon Carbide, and from 1600°C or more than that it is Super Kanthal. We customize according to the requirement.

- Versatile Operation :Suitable for a wide temperature range from 1200°C to 1800°C, accommodating various industrial applications with flexibility and reliability.

- Safety Features :Incorporates phase angle-controlled thyristor for power control, ensuring safe and stable operation, complemented by ammeter and indicator lights for real-time monitoring.

- Integrated Control Panel :Features an inbuilt control panel box for convenience, reducing footprint and simplifying installation.

- Adaptable Design :Customizable internal dimensions (ID and OD) to suit specific customer requirements, offering tailored solutions for diverse applications.

- Reliable Temperature Sensing :Pt-Rh13%/Pt 'R' type thermocouples with alumina beads ensure accurate temperature measurement, crucial for precise process control.

- Seamless Integration :Compatible with various gas control systems, featuring stainless steel fittings with water cooling arrangement and O-ring seals for controlled atmosphere applications.

- User-Friendly Interface :Intuitive control switches for mains and output, along with digital temperature display, facilitate easy operation and monitoring.

- Enhanced Safety Measures :Equipped with overcurrent protection via a 32A MCB (Miniature Circuit Breaker) for added safety during operation.

- Efficient Material Handling :Includes conical material feeding assembly and exhaust system with cyclone separators at both ends, ensuring smooth material flow and effective exhaust management.

- Programmable Rotary Motion :Powered by a 1 HP gear motor with variable frequency drive (VFD), offering programmable speed control (1-10 RPM) for precise rotation as per process requirements.

More Dental Furnaces

Box Furnace/ Muffle Furnace