This website is under development

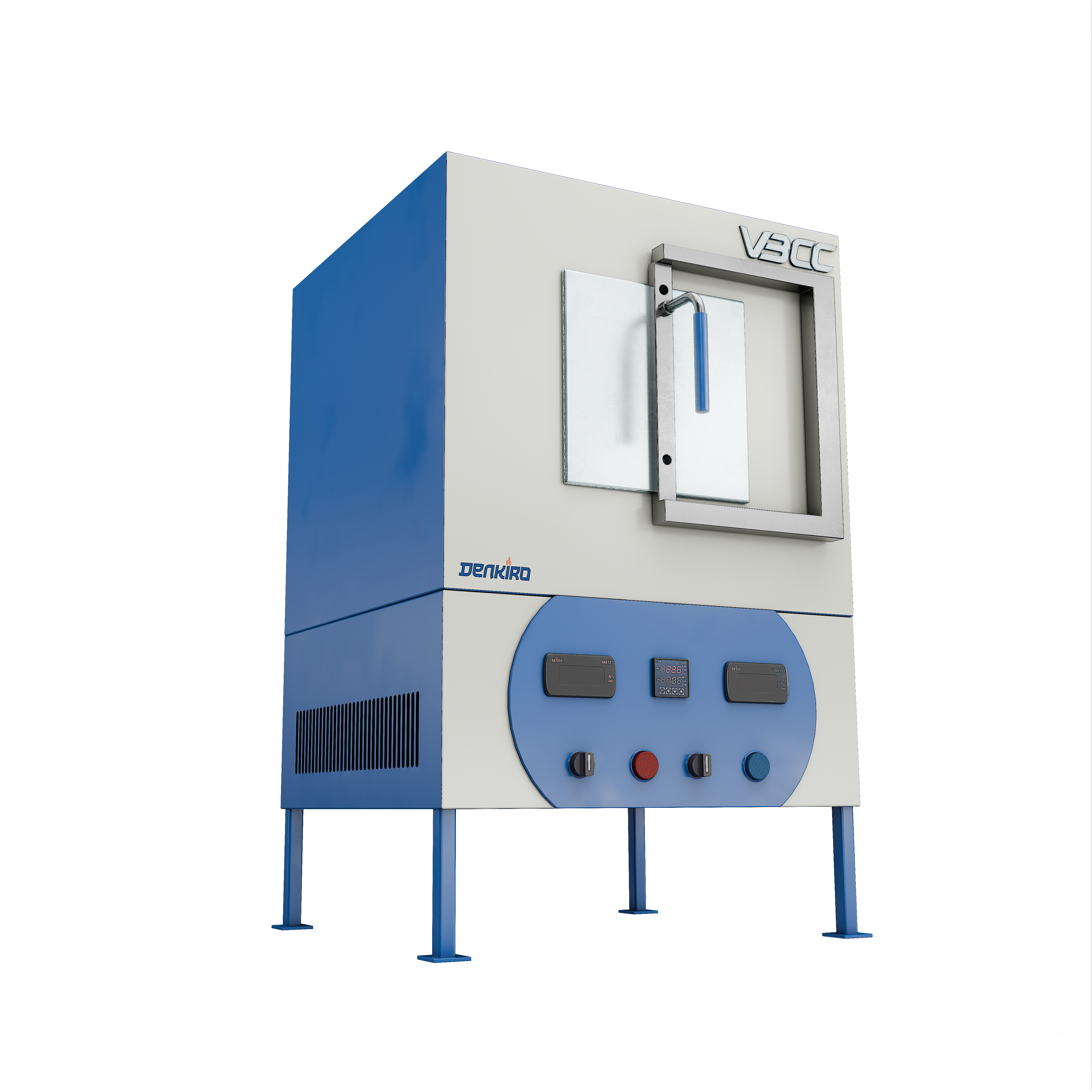

Horizontal cum Vertical Furnace

Denkiro is the dedicated sub-brand for electric furnaces under VBCC, embodying precision, efficiency, and innovation in thermal processing. Denkiro electric furnaces are designed to meet the high demands of various industries, offering reliable performance and cutting-edge technology.

- Compact Design :Horizontal cum vertical tubular furnace with shell size according to customer requirement.

- High-Temperature Capability :Capable of reaching temperatures up to 1800°C, ideal for processes requiring high heat.

- Robust Construction :Constructed with MS body and angle structure, featuring proper stiffeners and neat powder coat painting for durability and corrosion resistance.

- Premium Tubular Material :Working tube made of recrystallized alumina (99.8%), offering zero porosity and withstanding temperatures up to 1800°C, ensuring long-term durability and reliability.

- Precise Temperature Control :Equipped with a TAIE PID- 18*8=144 Segments, along with K-type thermocouples for accurate temperature monitoring and control.

- Efficient Heating System :Depending on the degree, the heating elements provide reliable and uniform heating, with a hot zone length of minimum 230mm, facilitating precise temperature control.

- Versatile Operation :Suitable for both single-phase AC operation, with a power requirement of 4 kW, catering to a wide range of industrial heating applications.

- Fast Heating Rate :Offers a heating rate of 10°C to 100°C, allowing for rapid temperature ramp-up and efficient processing.

- User-Friendly Interface :Features digital temperature and output indicators, along with control switches for mains and output, ensuring ease of operation and monitoring.

- Safety Features :Includes input and output fuses for enhanced safety during operation, providing protection against electrical faults.

- Reliable Power Control :Utilizes phase angle-controlled thyristers imported from SEMIKRON, Italy, ensuring stable and efficient power management.

- Gas Purging Capability :Equipped with two rotometers for gas purging, facilitating controlled atmosphere processes.

- Easy Installation :Requires a 32A MCB (single phase with neutral), ensuring compatibility with standard electrical setups and easy installation.

- Wide Range of Applications :Suitable for various heat treatment processes, research, and development applications, offering versatility, reliability, and precise temperature control.

- Heating Element Materials :Employs APM Kanthal heating elements, providing reliable heating performance up to 1200°C for continuous operation, even when tilted. Designed to accommodate different heating element materials such as silicon carbide for 1400°C and super Kanthal from 1600°C.

More Dental Furnaces

Box Furnace/ Muffle Furnace