This website is under development

Aluminum Stir Casting

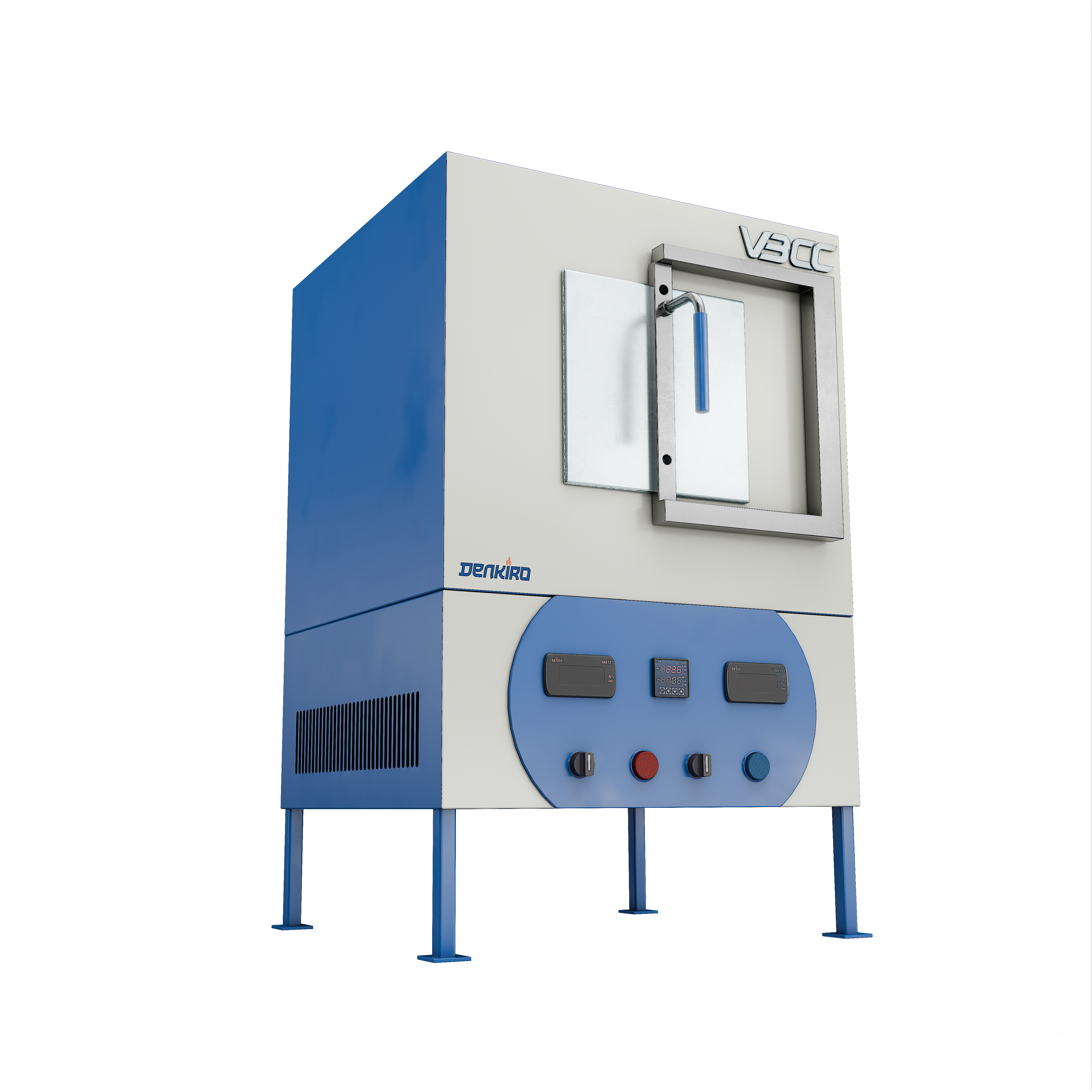

Denkiro is the dedicated sub-brand for electric furnaces under VBCC, embodying precision, efficiency, and innovation in thermal processing. Denkiro electric furnaces are designed to meet the high demands of various industries, offering reliable performance and cutting-edge technology.

- Advanced Crucible Furnace Design :Features an automatic melt casting system, ensuring efficient and precise operations for high-quality aluminium castings.

- Robust and Durable Construction :Made with thick gauge mild steel and reinforced with M.S. angles, the furnace is powder-coated for durability and long-lasting performance.

- Superior Insulation and Heating :Equipped with ceramic fiber insulation and advanced Kanthal heating elements, the furnace achieves a maximum temperature of 1100°C, maintaining a working temperature of 800°C with ease.

- High-Precision Temperature Control :The control panel includes a TAIE PID- 18*8=144 Segments programmer and digital temperature controller, providing accuracy within 1°C for precise thermal management.

- Efficient Power Management :Operates on a single-phase 230V AC supply with a power rating of 5 kW, and is designed to work seamlessly with a customer-provided 32 A MCB.

- Innovative Melt Discharge System :Features an automatic open/close mechanism at the crucible's bottom, operated via pneumatic control for smooth and controlled melt discharge.

- State-of-the-Art Stirring Mechanism :A high-speed stirrer, capable of 300 to 500 RPM, ensures thorough mixing.

- Premium Quality Crucible :Constructed from INCONEL alloy, the crucible includes a water-cooled top flange to maintain optimal conditions and support vacuum and gas purging processes.

- Precision Die Casting :Includes a grey cast iron steel mould with a vacuum connection, designed to shape the melt efficiently and enhance casting quality.

- Automated and Pneumatic Die Casting :The machine is equipped with a mini compressor and air tank, facilitating an automatic die casting process with pneumatic assistance for improved operational efficiency.

- Enhanced Operational Safety :Equipped with comprehensive safety features including input and output fuses, ensuring safe and reliable operation throughout the casting process.

More Dental Furnaces

Box Furnace/ Muffle Furnace