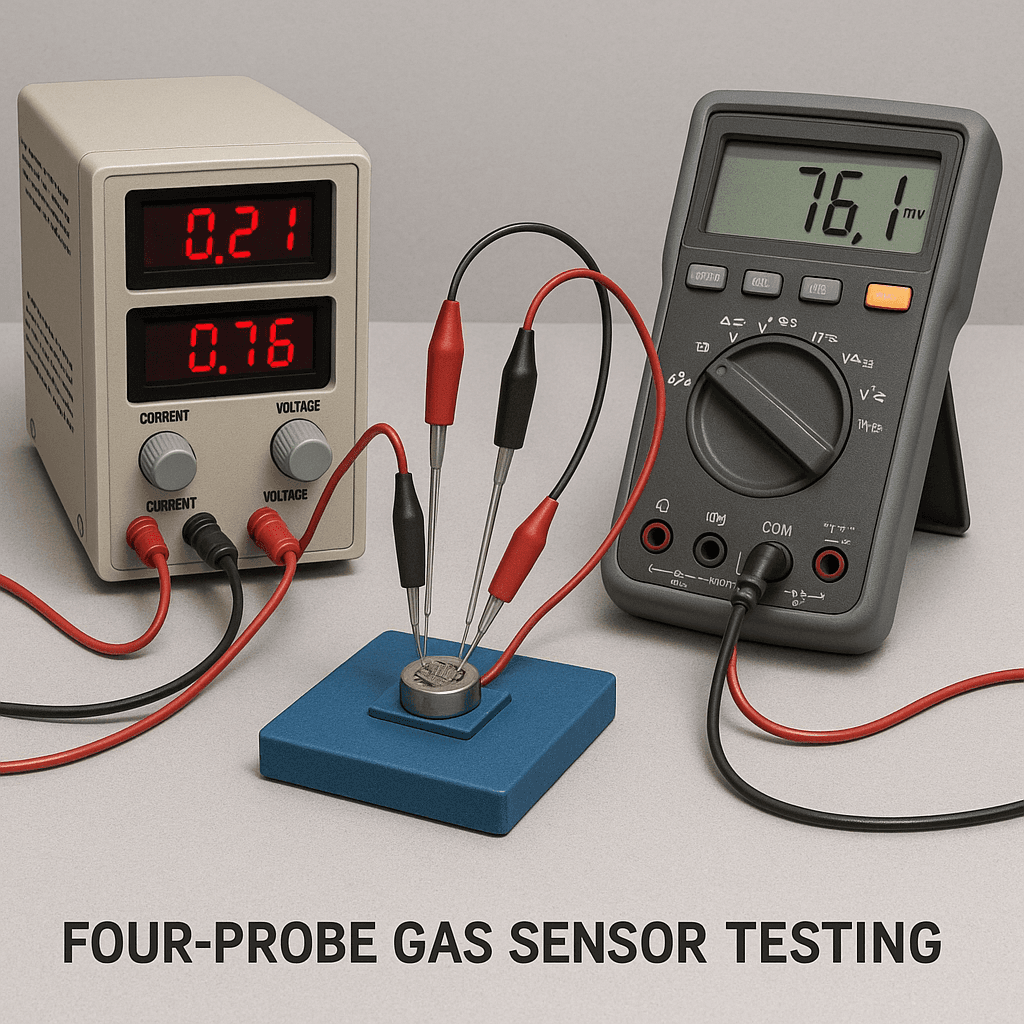

In the rapidly evolving field of sensor technology, precision and reliability are paramount—especially for semiconductor gas sensors used in critical applications like environmental monitoring, industrial safety, and medical diagnostics. One of the most trusted methods to evaluate the performance of gas sensors, particularly their electrical characteristics, is the four-probe method. But what exactly is a Four-Probe Gas Sensor Testing Unit, and how does it function? Let’s break it down.

What Is a Four-Probe Gas Sensor Testing Unit?

A Four-Probe Gas Sensor Testing Unit is a specialized apparatus designed to measure the electrical resistance or conductivity of a gas sensor material with high accuracy. This is especially crucial for semiconductor gas sensors, where the resistance of the material changes in response to different gas concentrations.

The unit typically includes:

- Four metallic probes (electrodes) positioned linearly and equally spaced

- An exceptionally precise system engineered to deliver current and monitor voltage

- A chamber where gas concentration, temperature, and humidity can be controlled

- Capability to integrate with data acquisition equipment or IoT platforms when required

This setup plays a critical role in gas sensor characterization, enabling researchers to evaluate and compare the behaviour of different materials under varied gas exposures.

Why Use the Four-Probe Method?

The four-probe method effectively minimizes the influence of contact and lead resistance—issues frequently encountered in conventional two-probe measurements. In a two-probe setup, the measured resistance comprises both the material’s intrinsic resistance and the resistance at the contact interfaces, which can reduce measurement accuracy.

In contrast, the four-probe technique uses:

- The outer probes introduce a steady current into the sensor material

- The inner probes measure the voltage difference that occurs across the material

This separation allows for highly precise readings of the material’s resistance, independent of the contact resistance at the electrodes. It is a standard approach in resistivity measurement for thin films and bulk materials used in gas sensing applications.

How Does It Work?

Understanding how a Four-Probe Gas Sensor Testing Unit operates involves both the physical configuration and the measurement process. Here's a detailed look at how the unit functions step by step:

Probe Configuration and Sensor Placement

The system uses four metallic probes—typically made from platinum, gold, or another conductive material—arranged in a straight line and spaced evenly. The semiconducting gas sensor material (often a thin film or a pellet) is placed so that all four probes contact its surface. Stable and reproducible contact is ensured using micromanipulators or spring-loaded contacts.

Current Injection Through Outer Probes

Probes 1 and 4, positioned on the outer ends, introduce a stable and known current (I) into the sensor material. As the current moves through the material, it generates a voltage difference resulting from the material's resistance.

Voltage Measurement via Inner Probes

The voltage drops (V) across the sensor material is measured by the two inner probes (Probes 2 and 3). This configuration ensures no current flows through the voltage probes, thereby eliminating contact resistance effects from the measurement.

Resistance Calculation Using Ohm's Law

After measuring the voltage and current, the resistance (R) can be determined using the formula.

R = V/I

This resistance value is key to gas sensor characterization, as it reflects the sensor's conductivity, which changes in the presence of target gases.

Gas Exposure and Sensor Response

The sensor is exposed to controlled environments where concentrations of gases like CO, NO₂, or H₂S are adjusted. The interaction causes measurable resistance changes due to redox reactions or surface adsorption—key mechanisms in semiconductor gas sensors.

The system continuously monitors resistance changes, providing insights into:

- Sensitivity

- Response time

- Recovery time

- Selectivity

Data Logging and Analysis

Modern systems offer digital interfaces for data logging and analysis, including real-time resistance tracking, temperature compensation, and export options—essential for accurate gas sensor characterization.

Key Applications

Four-probe testing systems for gas sensors find broad application in the following areas:

- Laboratories conducting research on material properties and gas sensor evaluation

- Quality control during sensor manufacturing

- Product development of novel semiconductor gas sensors

- Educational experiments in materials science and electronics

Advantages of the Four-Probe Testing Method

- High accuracy

- Minimized measurement error

- Non-destructive testing

- Compatible with various sensor materials (metal oxides, polymers, etc.)

- Suitable for analysing resistive properties of thin and compressed sensor materials

The four-probe gas sensor testing unit is an indispensable tool in the development and evaluation of semiconductor gas sensors. By ensuring accurate and reproducible resistivity measurements, it enables scientists and engineers to design sensors that are safer, smarter, and more responsive.

Whether you're conducting research on new sensing materials or validating the performance of a production batch, the four-probe method remains your gold standard for precision-driven gas sensor characterization.