In advanced thermal processing, flexibility and precision are crucial. The dual-operation tube furnace offers a flexible design capable of functioning in both horizontal and vertical orientations. Whether you're working in materials science, chemistry, or semiconductor fabrication, this hybrid design allows for expanded functionality without compromising temperature control or safety.

In this article, we explore the fundamentals of dual-operation tube furnaces, compare horizontal and vertical modes, and explain why this configuration is transforming the way researchers and engineers approach high-temperature applications.

What Is a Dual-Operation Tube Furnace?

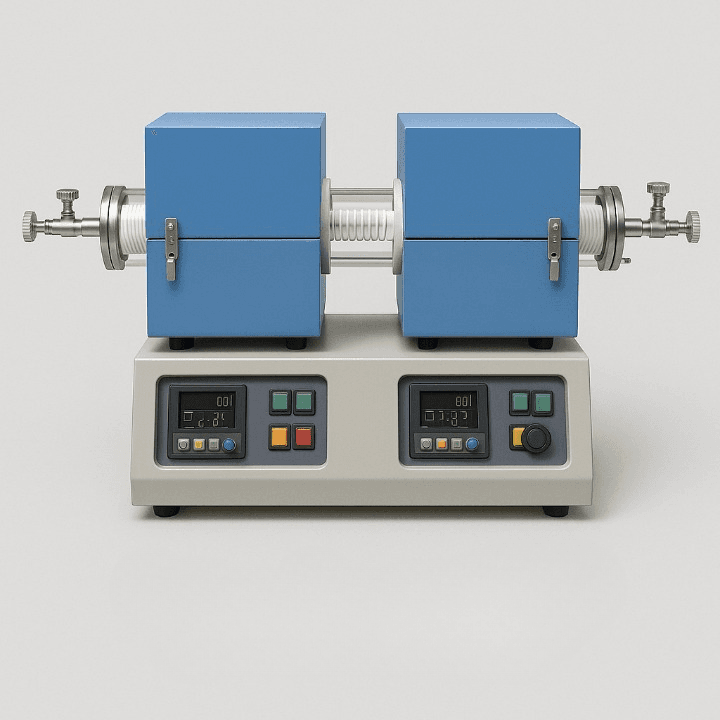

A dual-operation tube furnace is a specialized high-temperature furnace designed to function in both horizontal and vertical orientations. This flexibility provides significant advantages for a range of experimental and industrial processes.

While traditional tube furnaces are typically fixed in one orientation, a dual-operation model allows users to switch modes based on process requirements—whether it's gravity-assisted gas flow in vertical mode or uniform heat distribution in horizontal mode.

Key Features:

- Supports both vertical and horizontal operation modes

- High-temperature range (typically 1100°C to 1800°C)

- Works with multiple tube materials such as quartz, alumina, and others

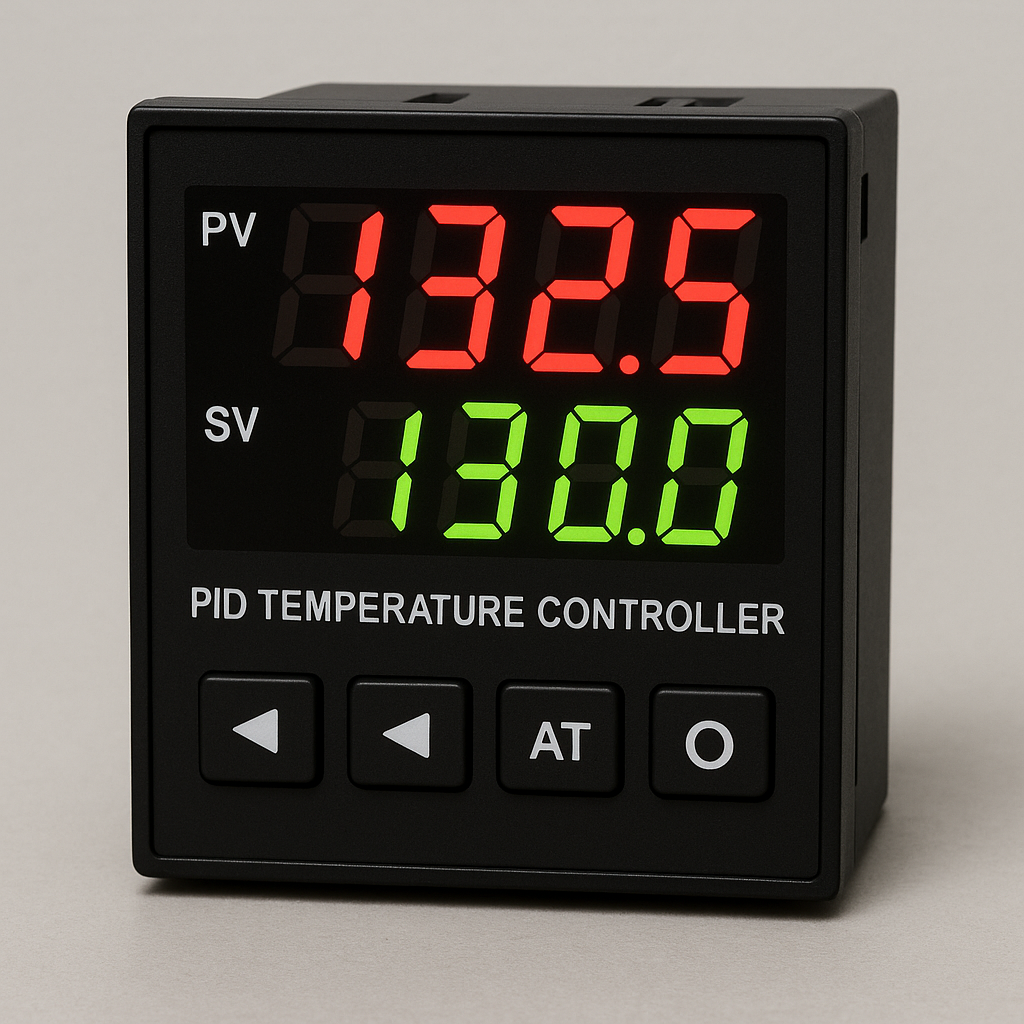

- Digital PID temperature control

- Vacuum or gas-controlled environment (optional)

Why Orientation Matters: Horizontal vs. Vertical Tube Furnace Modes

Each mode offers distinct benefits depending on the application. Here’s a breakdown:

Horizontal Tube Furnace Mode

Horizontal operation is the traditional layout for most tube furnaces.

Advantages:

- Uniform heating over a long sample length

- Simplifies the process of loading and removing samples in horizontal setups

- Ideal for: Annealing, Calcination, Solid-state diffusion and Oxidation/reduction reactions

Common Applications:

- Powder synthesis

- Ceramic sintering

- Semiconductor doping

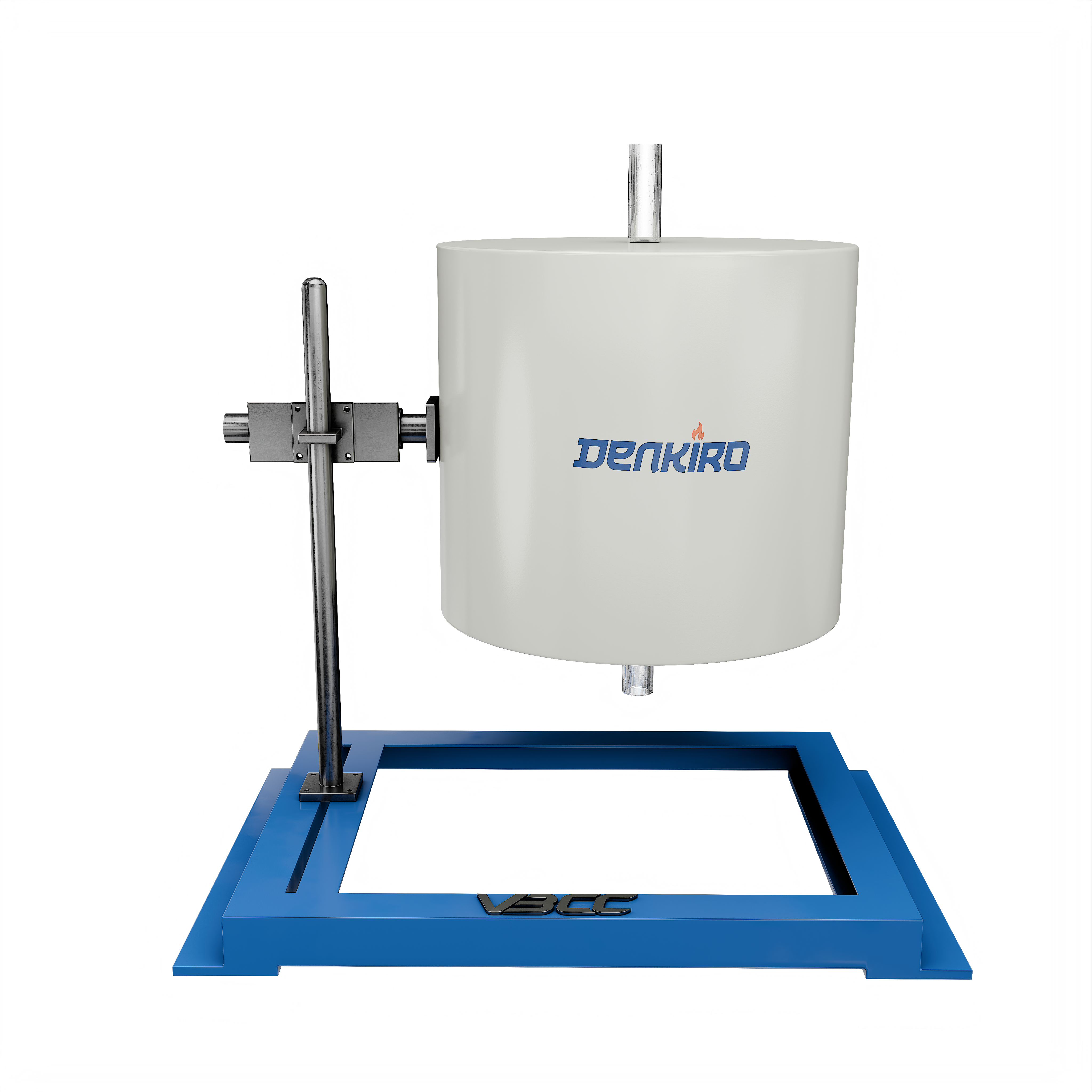

Vertical Tube Furnace Mode

Vertical operation positions the tube upright, which is ideal for processes that rely on gravity or vertical gas flow.

Advantages:

- Reduces particulate contamination (particles fall away from the hot zone)

- Gravity-assisted material flow (e.g., in chemical vapor deposition)

- Better gas flow dynamics in some reactions

Common Applications:

- CVD (Chemical Vapor Deposition)

- Vapor-phase reactions

- Crystal growth

- Nanowire synthesis

When to Use Each Mode

Solid Material Annealing

- Use horizontal mode

- Promotes consistent positioning of samples throughout the tube's length

Thin Film Deposition

- Use vertical mode

- Enables gravity-controlled gas flow and cleaner deposition

Powder Reactions

- Use horizontal mode

- Ideal for using flat crucibles and allows easier sample handling

Crystal Growth

- Use vertical mode

- Minimizes thermal gradients and improves material purity

Key Considerations When Using a Dual-Operation Tube Furnace

While dual-operation tube furnaces offer flexibility and space-saving advantages, optimal performance depends on proper setup, maintenance, and usage. Consider the following important factors:

1. Mounting & Structural Stability

- Ensure the furnace housing or frame is designed to support both horizontal and vertical configurations.

- Some models come with adjustable stands or swivel mounts—verify their load-bearing capacity and locking mechanisms.

- Improper mounting can lead to safety hazards or uneven heating performance, especially in vertical mode.

2. Tube Material Compatibility

Choose the appropriate tube material based on temperature and chemical reactivity:

- Quartz tubes: Up to ~1100°C, suitable for inert or oxidizing atmospheres

- Alumina tubes: Suitable for elevated temperatures (up to ~1700°C) and resistant to corrosive conditions

- Metal or graphite tubes: For reducing atmospheres or ultra-high-temperature processes

Thermal expansion behaviour varies by material—ensure proper sealing in both orientations.

3. Temperature Uniformity & Hot Zone Optimization

- Heating uniformity may vary between horizontal and vertical setups—refer to the manufacturer’s temperature profile for each mode.

- Position samples in the central “hot zone” to ensure consistent results.

- For temperature-sensitive processes like sintering or crystal growth, avoid placing materials near the furnace edges where thermal gradients may occur.

4. Gas Flow Configuration & Atmosphere Control

- In horizontal mode, gas typically flows linearly from one end to the other—ideal for continuous reactions or multiple samples.

- In vertical mode, gravity assists gas movement—especially useful for processes like CVD.

- Adjust flow rates, gas inlet/outlet positions, and sealing methods when switching orientations.

- Use vacuum flanges, O-rings, or inert gas purging systems as necessary.

5. Sample Orientation and Support

- Vertical operation requires careful support for loose powders or delicate substrates.

- Use appropriate holders, baskets, or crucibles with stable bases to prevent shifting.

- Horizontal mode generally allows easier use of boats, plates, and crucibles.

6. Safety Measures and Operator Training

- Switching between orientations introduces new safety considerations—train operators on correct handling for both configurations.

- Verify that all auxiliary systems (cooling, thermocouples, gas lines) operate correctly in both orientations.

- Always wear protective gear and monitor the furnace closely during reconfiguration.

7. Automation and Control Systems

- Some models feature smart controllers that store different programs for each mode.

- Ensure your PID temperature controller and sensors are calibrated appropriately for each orientation, as sensor response may vary.

- Log data for each run to monitor consistency and detect performance deviations.

Why Dual-Operation Furnaces Are Gaining Popularity

With lab space becoming more limited and research demands growing, the dual-operation tube furnace is becoming a preferred choice. Instead of investing in two separate furnaces—one vertical and one horizontal—labs can opt for a single, hybrid unit that offers both capabilities. It helps minimize expenses, conserve space, and improve overall process versatility.

For research institutions and manufacturing labs working across multiple thermal processes, the ability to switch easily between horizontal tube furnace and vertical tube furnace configurations greatly boosts productivity and project diversity.

A dual-operation tube furnace delivers the best of both worlds—the even heating and accessibility of a horizontal tube furnace, and the process-specific precision of a vertical tube furnace. Whether you're developing new materials, running gas-phase reactions, or pushing the boundaries of high-temperature furnace applications, this versatile system is a smart, future-ready investment.