When it comes to creating durable, aesthetically pleasing dental restorations, sintering plays a crucial role. This high-temperature process is especially important for materials like zirconia, which is widely used for dental crowns, bridges, and other restorations due to its strength, biocompatibility, and natural appearance. In this blog, we’ll explore the science of sintering zirconia and how advanced furnaces are enhancing outcomes in dental restoration.

What is Sintering?

Sintering is the process of heating a powdered material, like zirconia, to a temperature below its melting point, causing the particles to bond together and form a solid structure. In dental restorations, this process is critical because it transforms zirconia from a soft, porous state into a dense, strong material that can withstand the forces of chewing and provide a natural appearance in the mouth.

For zirconia, the sintering process not only densifies the material but also enhances its mechanical properties, such as strength and fracture resistance. Additionally, sintering affects the translucency and overall aesthetic qualities of zirconia, ensuring it matches the look of natural teeth.

The Science Behind Sintering Zirconia

Zirconia (ZrO₂) is a ceramic material that undergoes a phase transformation during the sintering process. Initially, it exists in a tetragonal phase, which is stable at higher temperatures. However, as it cools during sintering, zirconia can transition to a monoclinic phase, which is more stable at room temperature but less dense. This transformation can cause slight expansion, which is beneficial for improving the material's fracture toughness. The final sintered zirconia structure achieves a balance between strength and aesthetic properties, making it ideal for dental applications.

The sintering process typically involves the following steps:

- Preheating: The zirconia is slowly heated to ensure uniform temperature distribution, which prevents cracking or warping.

- Sintering: The material is heated to its maximum sintering temperature (usually around 1500–1600°C for zirconia) to achieve densification.

- Cooling: Gradual cooling is necessary to prevent stress and ensure the material retains its strength.

Advanced Furnaces in the Sintering Process

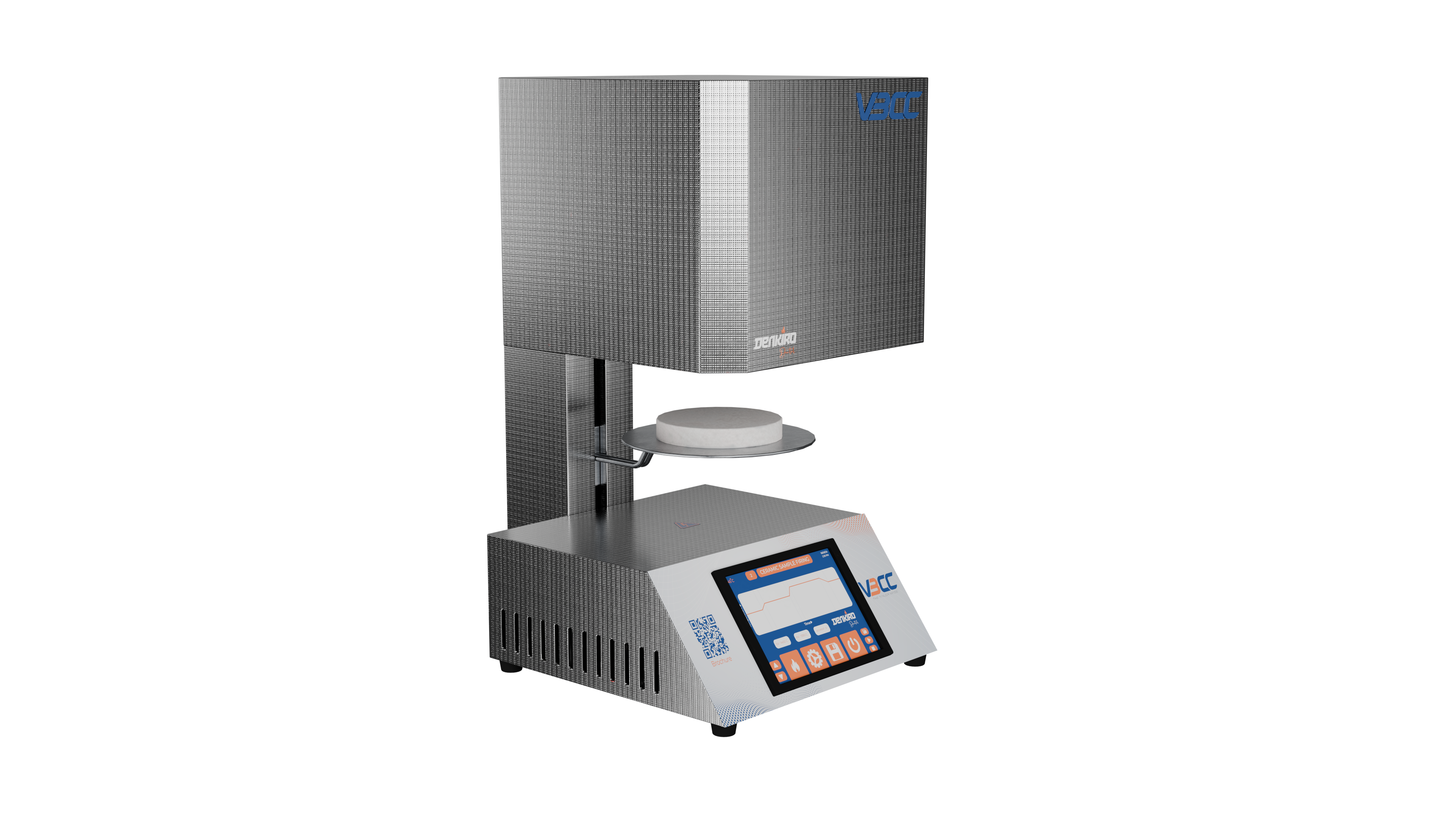

While the concept of sintering is straightforward, the technology behind dental furnaces has advanced significantly, allowing for more precise control over the process. Traditional furnaces could only offer basic temperature control, but modern sintering furnaces, such as the ones used for zirconia restorations, feature several key innovations that improve the quality of dental products.

- Precise Temperature Control: Advanced furnaces, like those from VBCC, offer exceptional temperature stability and uniformity. This ensures that zirconia is sintered evenly, preventing issues like thermal gradients that could lead to cracks or inconsistencies.

- Faster Sintering: Newer furnaces can sinter zirconia at a faster rate without sacrificing the material’s properties. This is particularly valuable in busy dental labs, where time efficiency is key.

- Atmosphere Control: Modern furnaces offer the ability to control the atmosphere inside the chamber. This is important for zirconia sintering, as oxygen levels can influence the colour and translucency of the material. A controlled atmosphere ensures optimal results, preventing undesirable discoloration and enhancing the aesthetic quality of the final restoration.

- Microwave Technology: Some of the latest innovations in furnace technology include microwave-assisted sintering. This method uses electromagnetic radiation to heat zirconia more evenly and rapidly than conventional methods, resulting in stronger and more aesthetically pleasing restorations.

- Automated Programs: Many modern sintering furnaces come with pre-programmed settings for different materials, making the process easier and reducing the chances of human error. Dental technicians can rely on the furnace to achieve optimal results without constant monitoring.

Improving Outcomes with Advanced Furnaces

The sintering process is the heart of creating strong, reliable, and aesthetic dental restorations. With advancements in furnace technology, dental professionals can achieve even better results. These technologies not only enhance the strength and durability of zirconia restorations but also improve their appearance, ensuring they blend seamlessly with natural teeth.

Furnaces that provide precise control over temperature, atmosphere, and sintering speed are crucial for achieving consistent outcomes. With these innovations, dental restorations made from zirconia are now more robust, visually appealing, and longer-lasting than ever before.

The sintering process is a critical component in the creation of zirconia dental restorations, transforming the material into a durable and aesthetically pleasing solution for patients. With the latest furnace technologies offering enhanced control, faster processing, and better outcomes, dental labs can produce superior restorations with greater ease. As advancements in furnace technology continue, the future of dental restoration looks brighter than ever.