Vacuum Hot Press equipment is an indispensable tool in modern manufacturing and research, enabling the production of high-quality components with exceptional precision. By applying simultaneous heat and pressure under a vacuum environment, this technology ensures superior material properties, such as enhanced density, improved mechanical strength, and reduced porosity. In this blog, we explore the top applications of Vacuum Hot Press equipment across various industries.

1. Aerospace Industry

The aerospace sector demands materials that can withstand extreme temperatures and pressures while maintaining lightweight properties. Vacuum Hot Press equipment is essential for manufacturing high-performance components such as:

- Ceramic matrix composites (CMCs): Used in turbine blades and heat shields

- Metal matrix composites (MMCs): For lightweight and durable structural parts

- Engine components: High-temperature-resistant alloys formed with unparalleled precision using Vacuum Hot Pressing

Additionally, vacuum heat treatment during the pressing process further enhances the thermal and mechanical properties of aerospace materials.

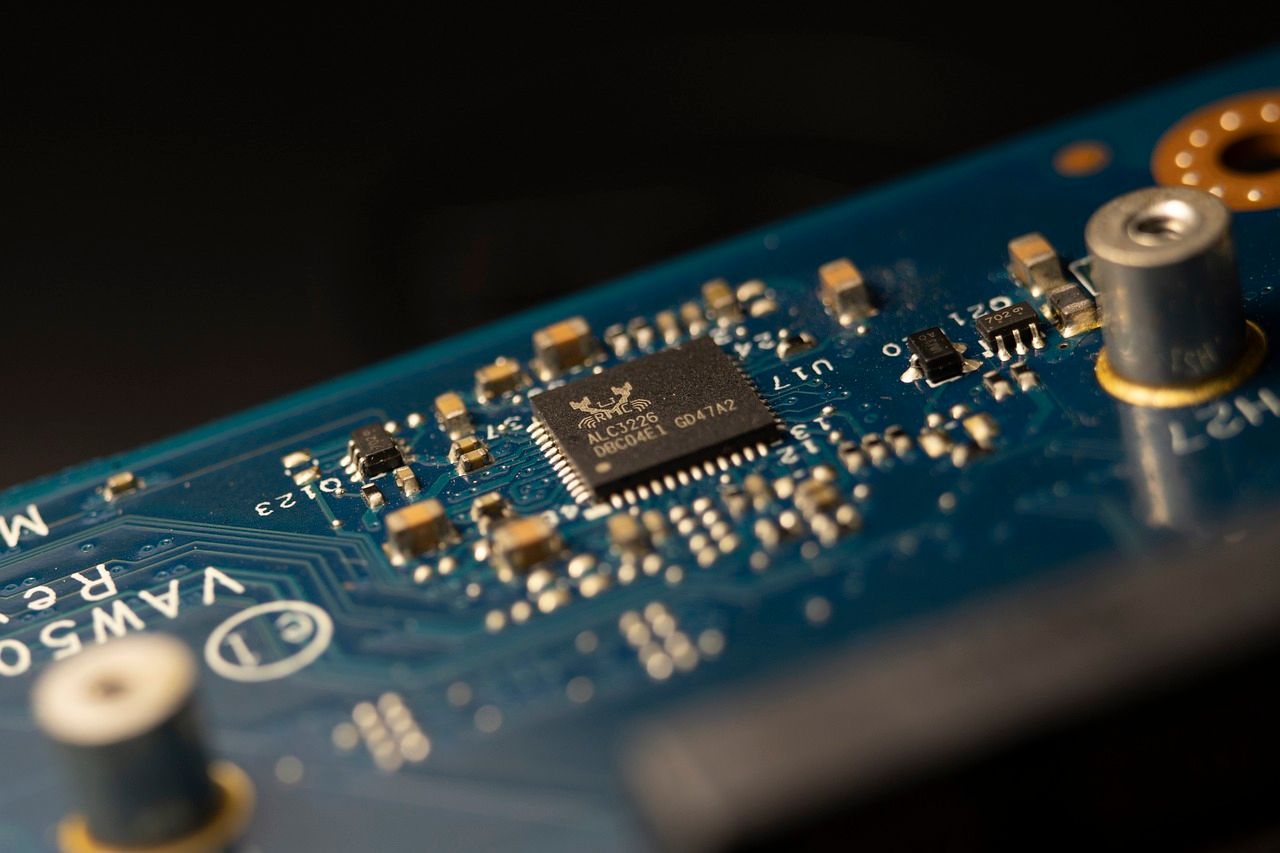

2. Electronics and Semiconductor Industry

In the electronics sector, precision and material purity are paramount. Vacuum Hot Presses are widely used to produce:

- Substrates for microchips: High-density ceramics like alumina and aluminium nitride

- Semiconductor components: Bonding and sintering of wafers and electronic circuits

- Thermal management materials: Heat spreaders and insulators for electronic devices

Vacuum Hot Pressing ensures minimal contamination and optimal material properties, critical for the performance of electronic components.

3. Automotive Industry

With the rise of electric vehicles (EVs) and advanced combustion engines, Vacuum Hot Press technology plays a critical role in automotive manufacturing. Key applications include:

- Battery components: Sintering of cathodes and anodes for lithium-ion batteries

- Friction materials: Production of wear-resistant brake pads and clutch discs

- Lightweight structures: Fabrication of aluminium and titanium alloys for reduced vehicle weight

The integration of vacuum heat treatment enhances the durability and performance of these automotive components.

4. Energy and Power Generation

Vacuum Hot Press equipment contributes significantly to the energy sector, particularly in renewable energy and power generation. Applications include:

- Fuel cells: Manufacturing dense, defect-free ceramic components for solid oxide fuel cells (SOFCs)

- Solar panels: Bonding materials for photovoltaic cells to improve efficiency using Vacuum Hot Press for diffusion bonding

- Turbine blades: High-strength alloys for gas and steam turbines

The ability of Vacuum Hot Presses to create defect-free, high-strength materials is crucial for the energy sector's demands.

5. Medical Industry

The medical field benefits greatly from Vacuum Hot Press technology, especially in producing biocompatible materials and devices. Examples include:

- Dental implants: High-density ceramics like zirconia for long-lasting performance

- Orthopaedic components: Sintering of titanium alloys for prosthetics and implants

- Surgical tools: Durable, high-precision instruments made from specialized metals

6. Research and Development (R&D)

R&D facilities across industries use Vacuum Hot Presses to develop innovative materials and processes. Applications include:

- Advanced materials: Experimentation with composites, ceramics, and alloys

- Prototyping: Rapid production of test samples for performance evaluation

- Material property enhancement: Research on Vacuum Hot Pressing techniques to improve density and strength

7. Defence and Military

The defence industry requires high-performance materials for critical applications. Vacuum Hot Press equipment aids in producing:

- Ballistic armour: Dense ceramics like boron carbide for lightweight yet robust armour

- Aerospace-grade materials: Advanced composites for fighter jets and missiles

- Thermal protection systems: Components for hypersonic vehicles

8. Nuclear Industry

In nuclear applications, materials must endure radiation and extreme environments. Vacuum Hot Presses are instrumental in:

- Fuel pellets: Sintering uranium oxide pellets for nuclear reactors

- Radiation shielding materials: Dense components to protect against radioactive exposure

- Structural parts: High-strength materials for reactor cores and containment systems

Vacuum Hot Press equipment is a cornerstone of modern manufacturing, enabling breakthroughs across industries by delivering materials and components with exceptional precision and properties. From aerospace and electronics to energy and medical applications, its versatility continues to drive innovation and meet the demands of cutting-edge technologies.