If you work in materials science, ceramics, metallurgy, or industrial research, you’ve probably heard the terms furnace, kiln, and oven used—sometimes interchangeably. Although each one generates heat, they differ significantly from one another. Choosing the wrong equipment can affect test results, product quality, and even safety.

In this guide, we’ll break down the key differences in design, temperature range, applications, and performance so you can make the right choice for your work.

1. The Basics: Definitions

Before diving into differences, let’s define each:

- Laboratory Furnace – A high-temperature heating device designed for research, testing, and industrial applications, capable of precise temperature control often exceeding 1,000°C (1,832°F).

- Kiln – Traditionally used for ceramics and pottery, kilns are designed to fire clay, glass, and other materials, usually operating between 600°C and 1,400°C (1,112–2,552°F).

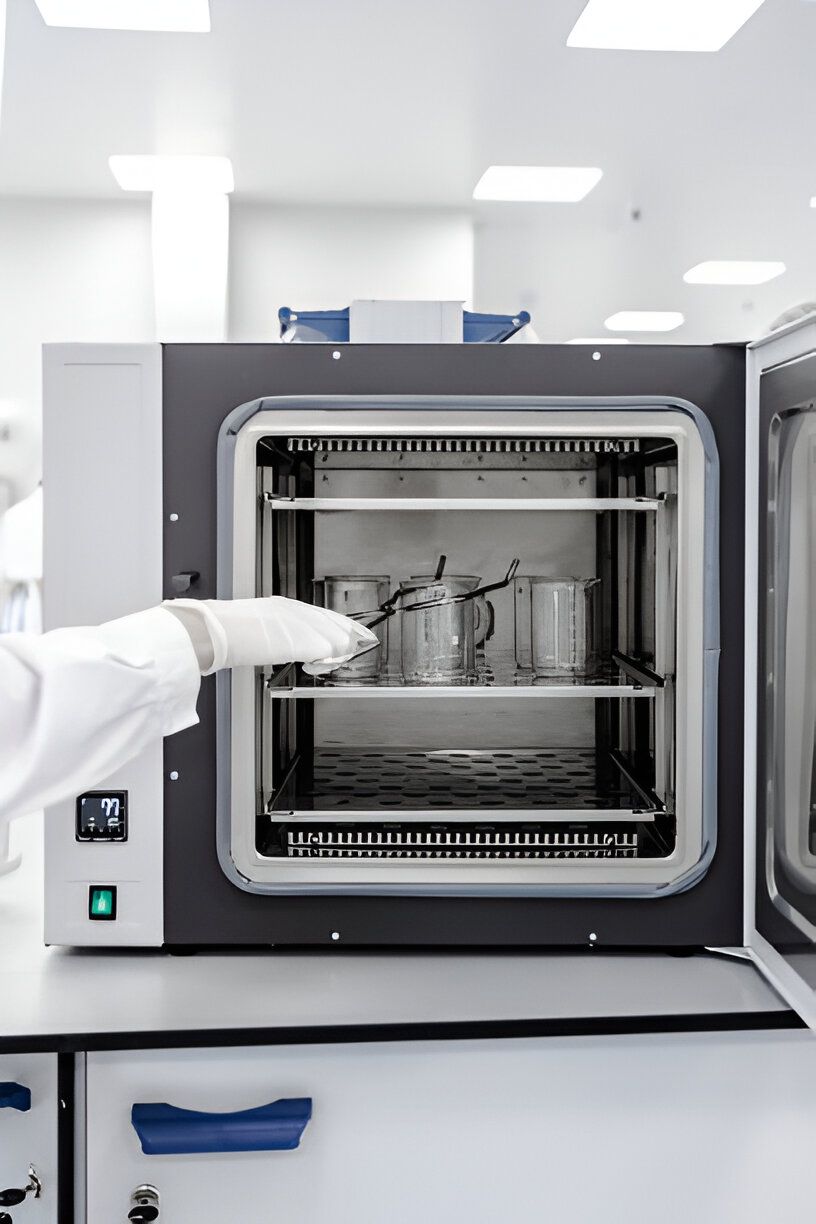

- Laboratory Oven – A controlled heating chamber for drying, curing, or baking materials, generally operating below 300°C (572°F) and focusing on uniform, gentle heating.

2. Temperature Ranges

One of the easiest ways to tell them apart is by maximum operating temperature:

- Laboratory Furnace – Typically operates between 1,000°C and 1,800°C. Appropriate for applications such as metal heat treatment, ceramic sintering, material combustion analysis, and other operations requiring elevated temperatures.

- Kiln: Typically operates within the 600°C to 1,400°C range, depending on the firing requirements and material type.

- Oven: Typically operates within a temperature range of about 100°C to 300°C. Ideal for drying samples, curing adhesives, and low-temperature baking processes.

3. Atmosphere Control

Temperature isn’t the only factor—atmosphere control is crucial for certain processes.

- Laboratory Furnaces can operate in air, vacuum, or controlled gas atmospheres (e.g., nitrogen, argon, hydrogen), which is essential for oxidation-sensitive materials.

- Kilns traditionally run in ambient air but can be modified for reduction or oxidation firing in ceramics.

- Ovens are almost always air-heated without specialized atmospheric control.

4. Precision & Control

- Furnaces: Offer tight temperature tolerances (±1–2°C), programmable ramps, and multi-zone heating for uniform results.

- Kilns: Provide decent control for art and industrial ceramics but less fine-tuned than laboratory furnaces.

- Ovens: Focus on uniform airflow and gentle heating rather than extreme precision at high temperatures.

5. Applications Breakdown

Laboratory Furnace:

- Heat treatment of metals and alloys

- Sintering of ceramics or powder metallurgy components

- Ash content determination

- Material property testing under controlled atmospheres

Kiln:

- Pottery and ceramic firing

- Glass slumping or fusing

- Enameling and glaze firing

Oven:

- Sample drying and moisture removal

- Polymer curing

- Baking composite materials at low temperatures

6. Construction Differences

- Furnace: Heavy-duty insulation (often refractory bricks or ceramic fiber), high-grade heating elements (molybdenum disilicide, Kanthal, silicon carbide), advanced controllers.

- Kiln: Thicker walls for heat retention, often top-loading or front-loading, designed for batch firing cycles.

- Oven: Built with lighter insulation materials and a stainless-steel interior, incorporating convection fans to circulate heated air evenly throughout the chamber.

7. Which One Should You Choose?

- Choose a laboratory furnace if your work demands high temperatures, precise control, or specialized atmospheres—especially for metals, ceramics, or advanced materials.

- Choose a kiln if you’re working mainly with ceramics, glass, or artistic firing where ultra-precise temperature accuracy is less critical than heat retention and firing profile.

- Choose an oven if your process is low-temperature and focuses on drying, curing, or gentle heating.

While laboratory furnaces, kilns, and ovens may all seem like "things that get hot," their design, capabilities, and purposes differ significantly. Choosing the right one comes down to temperature needs, atmosphere requirements, and the level of control your process demands.

Using the right heating equipment is more than a matter of efficiency—it’s the difference between accurate results and costly errors.