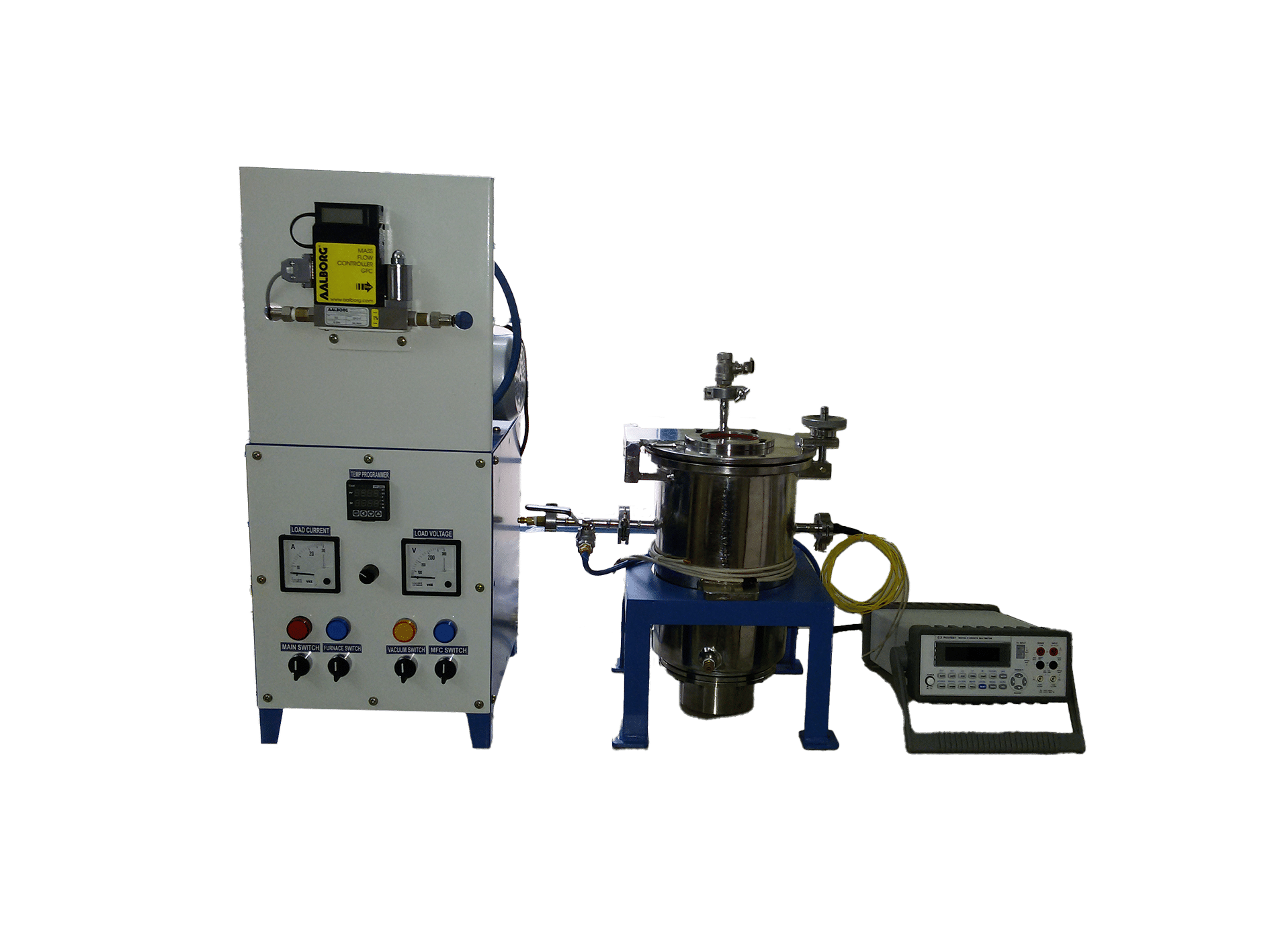

Plasma Assisted Metal Oxide CVD (MOCVD)

Special Research Equipment

Advanced thin film deposition is achieved through VBCC's Plasma Assisted Metal Oxide CVD system.

₹ Enquire for Estimate

contact us

contact us

Specifications

*Customizable to your Requirements

/2.jpg?updatedAt=1707200758002)

/2.jpg?updatedAt=1707200758002)

/3.jpg?updatedAt=1707200758191)

/4.jpg?updatedAt=1707200758744)

/5.jpg?updatedAt=1707200758724)

/6.jpg?updatedAt=1707200759137)

Overview

- VBCC's Plasma Assisted Metal Oxide CVD (MOCVD) system is an advanced deposition tool that brings precision and control to the synthesis of thin films. With a focus on cutting-edge materials engineering, this equipment plays a pivotal role in industries such as semiconductor manufacturing, optoelectronics, and advanced coatings.

- Key Features:

1. High-Precision Film Deposition:

The MOCVD system utilizes plasma assistance to achieve high-precision deposition of metal oxide thin films. This ensures uniform coatings with exceptional quality, meeting the stringent requirements of modern technological applications.

2. Versatility in Materials Synthesis:

Tailored for diverse applications, the system accommodates a wide range of metal-organic precursors, allowing researchers and manufacturers to synthesize complex metal oxide materials with varying compositions and properties.

3. Controlled Growth Conditions:

Offering precise control over growth conditions, the MOCVD system enables researchers to manipulate parameters such as temperature, pressure, and gas flow rates. This level of control is crucial for tailoring material characteristics and performance.

4. Advanced Semiconductor Fabrication:

In semiconductor manufacturing, the MOCVD system facilitates the deposition of critical metal oxide layers with exacting precision, contributing to the development of high-performance electronic and optoelectronic devices.

5. User-Friendly Interface:

Equipped with a user-friendly interface, the system allows operators to program and monitor deposition processes easily. This intuitive control enhances efficiency in research and production environments.

- VBCC's Plasma Assisted Metal Oxide CVD (MOCVD) system stands as a testament to the company's commitment to providing state-of-the-art equipment for materials synthesis, supporting advancements in technology and innovation across various industries.