Enamel Furnace

Industrial Furnaces

The Enamel Furnace from VBCC ensures efficient and uniform enamel coating for diverse applications, meeting high-quality standards.

₹ Enquire for Estimate

contact us

contact us

Specifications

*Customizable to your Requirements

Overview

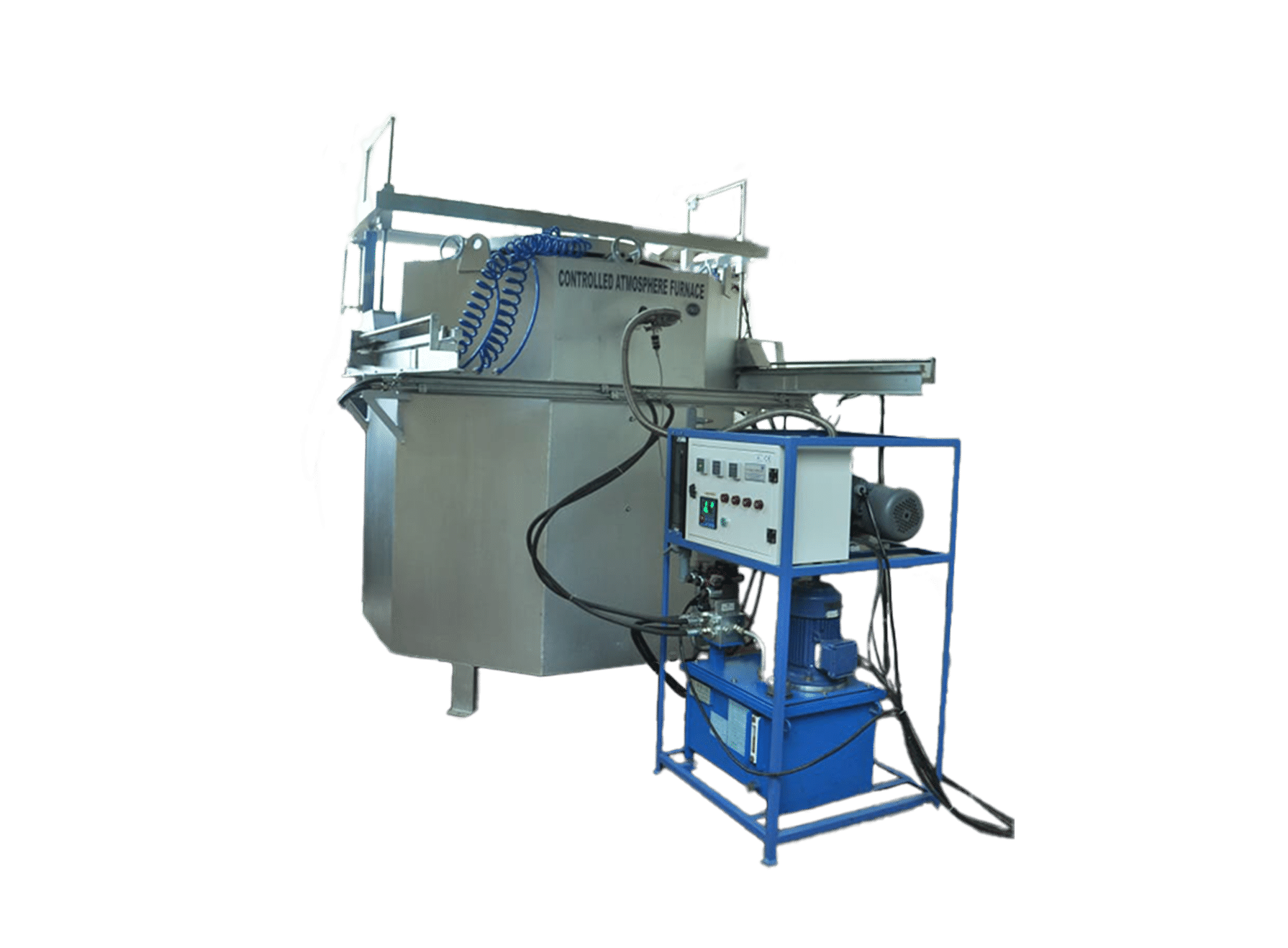

- VBCC's Enamel Furnace is a specialized heating system designed for the firing and curing processes involved in enamel coating applications. This furnace is tailored to provide controlled temperature environments, ensuring the proper fusion and adhesion of enamel layers to various substrates.

- Key Features:

1. Precise Temperature Control:

The Enamel Furnace is equipped with precise temperature control systems, allowing for accurate and consistent temperature management during the firing process. This precision is crucial for achieving desired enamel properties.

2. Uniform Heating Across Substrates:

The furnace design ensures uniform heating across the enamel-coated substrates, preventing uneven curing and ensuring a consistent finish. This is essential for producing high-quality enamel-coated products.

3. Customizable Firing Profiles:

Users have the flexibility to customize firing profiles based on the specific requirements of different enamel compositions and substrates. This adaptability allows for optimal results in various enamel coating applications.

4. Controlled Atmosphere:

The furnace may include features for maintaining a controlled atmosphere during the firing process, minimizing the risk of oxidation or other undesirable reactions that could affect the enamel coating.

5. High-Temperature Capability:

Designed to accommodate the elevated temperatures required for enamel firing, the furnace ensures that the enamel reaches its melting point, facilitating proper fusion and adhesion to the substrate.

6. Versatility in Enamel Applications:

The Enamel Furnace is suitable for a range of enamel applications, including those in the automotive, household, and industrial sectors. It can be employed for coating materials such as metals, ceramics, and glass.

7. Efficient Heat Transfer:

The furnace design optimizes heat transfer to the enamel-coated surfaces, promoting efficient curing and resulting in a durable and aesthetically pleasing enamel finish.

8. Advanced Safety Features:

The furnace is equipped with user-friendly controls that allow operators to monitor and adjust the firing parameters easily, ensuring a streamlined and efficient enamel coating process.

- VBCC's Enamel Furnace represents the company's commitment to providing specialized solutions for the enamel industry. With its precise temperature control, uniform heating, and versatility, the furnace contributes to the production of high-quality enamel-coated products across various applications.